Pogo Pins Catalog

One of our key offerings is pogo pins, which are spring-loaded contact pins extensively utilized in electronic devices. These pins serve as a dependable and efficient means for establishing temporary electrical connections, facilitating the seamless connection and disconnection of various components, such as circuit boards or test probes. This process is not only compact but also highly repeatable, ensuring reliability in critical applications

Our company specializes in manufacturing components, sub-components, and sub-systems primarily tailored for the semiconductor, medical, military, and industrial sectors.

We are dedicated to providing our customers with top-notch technologies, service, be it technical support, punctual deliveries, or tailored customizations – always with the goal of enhancing value for our clients.

Waterproof Connectors

View ProductComplex Industrial Connectors

View ProductTarget Pins – TP 5330

View ProductTarget Pins – TP 5329

View ProductTarget Pins – TP 5328

View ProductTarget Pins – TP 5327

View ProductStandard Connectors – H2014012AD

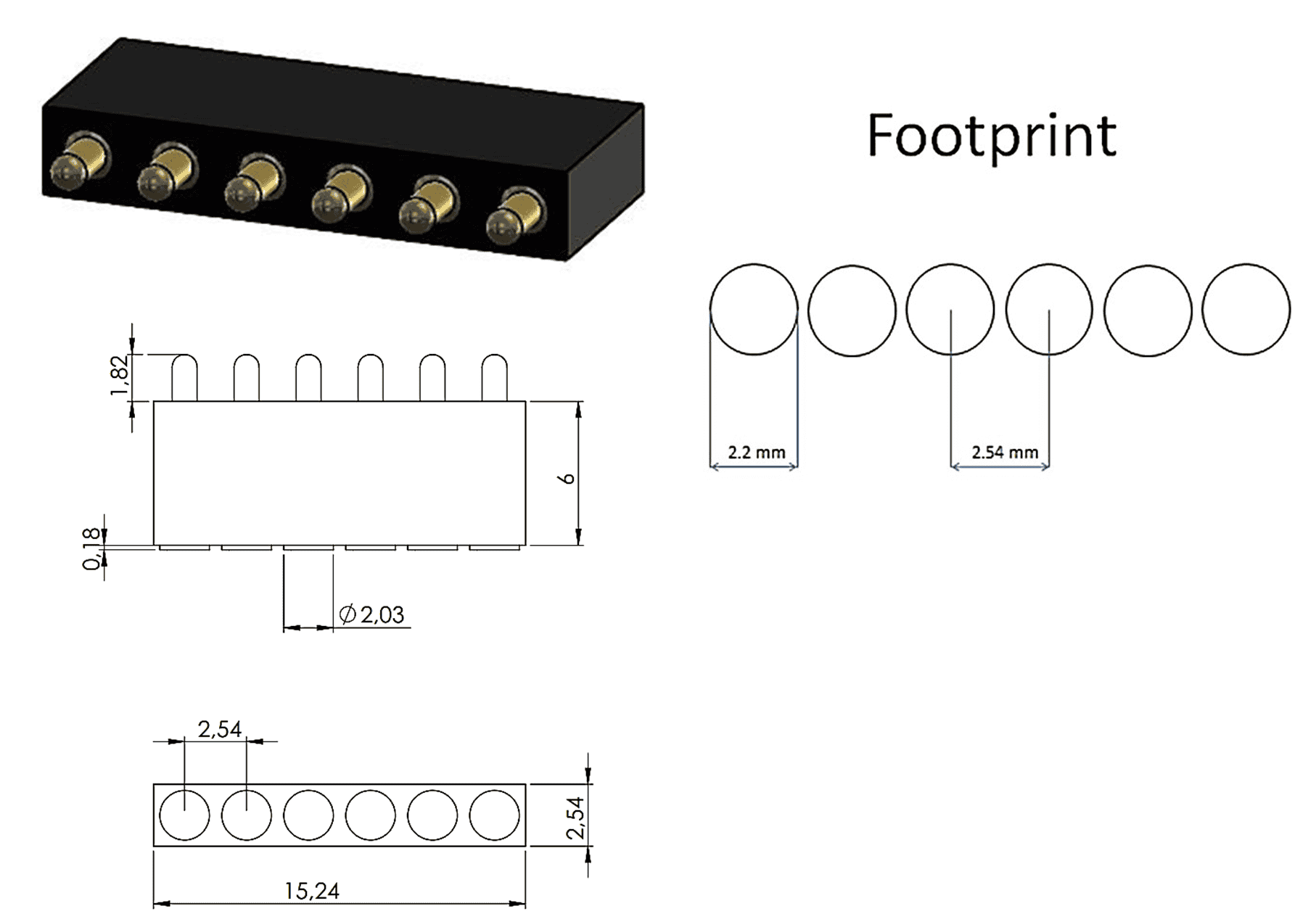

View ProductStandard Connectors – 6 Pin Headers

View ProductModular Connectors

View ProductC Series – Thru Hole

View ProductC Series – Surface Mount

View ProductC Series – Solder Cup

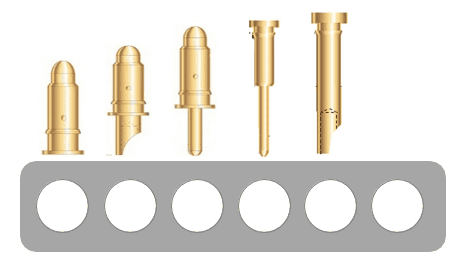

View ProductBattery & Connector Pins – BC201515AD

View ProductBattery & Connector Pins – BC201512AD

View ProductBattery & Connector Pins – BC201478AD

View ProductBattery & Connector Pins – BC201460AD (Target Spring Probe)

View ProductBattery & Connector Pins – BC201415AD

View ProductBattery & Connector Pins – BC201412AD

View ProductBattery & Connector Pins – BC201355AD

View ProductBattery & Connector Pins – BC201352AD

View ProductBattery & Connector Pins – BC201349AD

View ProductBattery & Connector Pins – BC201346AD

View ProductBattery & Connector Pins – BC201343AD

View ProductBattery & Connector Pins – BC201340AD

View ProductBattery & Connector Pins – BC201337AD

View ProductBattery & Connector Pins – BC201334AD

View ProductBattery & Connector Pins – BC201331AD

View ProductBattery & Connector Pins – BC201328AD

View ProductBattery & Connector Pins – BC201325AD

View ProductBattery & Connector Pins – BC201319AD

View ProductBattery & Connector Pins – BC201316AD

View ProductBattery & Connector Pins – BC201313AD

View ProductBattery & Connector Pins – BC201310AD

View ProductBattery & Connector Pins – BC201307AD

View ProductBattery & Connector Pins – BC201304AD

View ProductBattery & Connector Pins – BC201301AD

View ProductPrecision and Reliability of Pogo Pins

Admati’s pogo pins are engineered for stable, low-resistance contact under repeated use.

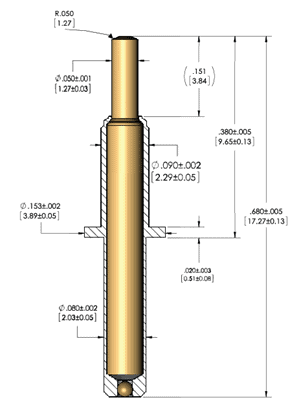

Tight mechanical tolerances and controlled spring forces deliver consistent compression and signal integrity over long service life.

High-conductivity materials and hard gold over nickel plating minimize contact resistance and protect against oxidation and wear, while optional “super plating” adds extended protection against galvanic corrosion in harsh environments.

Select families support high current and high-cycle operation—up to hundreds of thousands of mating cycles—validated by rigorous in-house QA using CMMs, height gauges, calipers, and micrometers for dimensional accuracy and repeatability.

Custom Pogo Pin Configurations

- Catalog breadth: target pins, battery/charging contacts, modular and standard headers, and waterproof pogo-pin connectors.

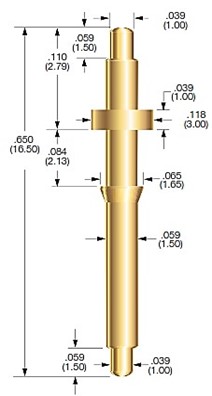

- Mounting/termination: C-Series options for thru-hole, surface-mount, and solder- cup; single pins or multi-pin arrays.

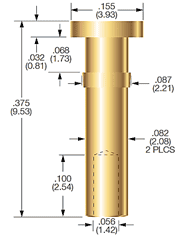

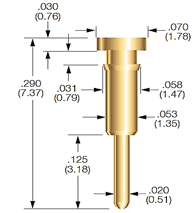

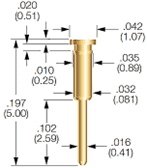

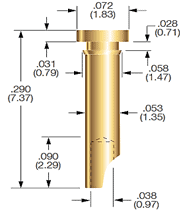

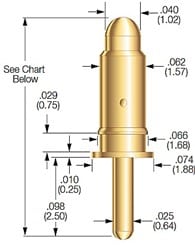

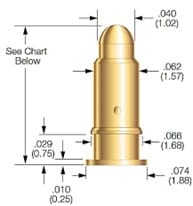

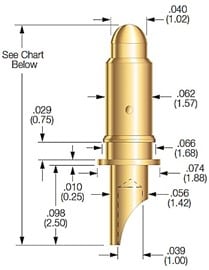

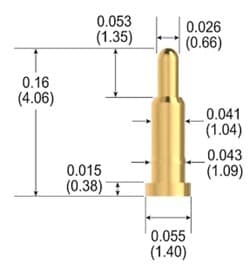

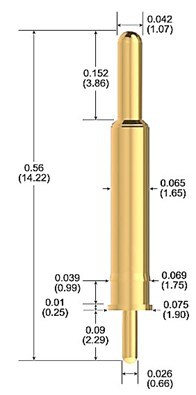

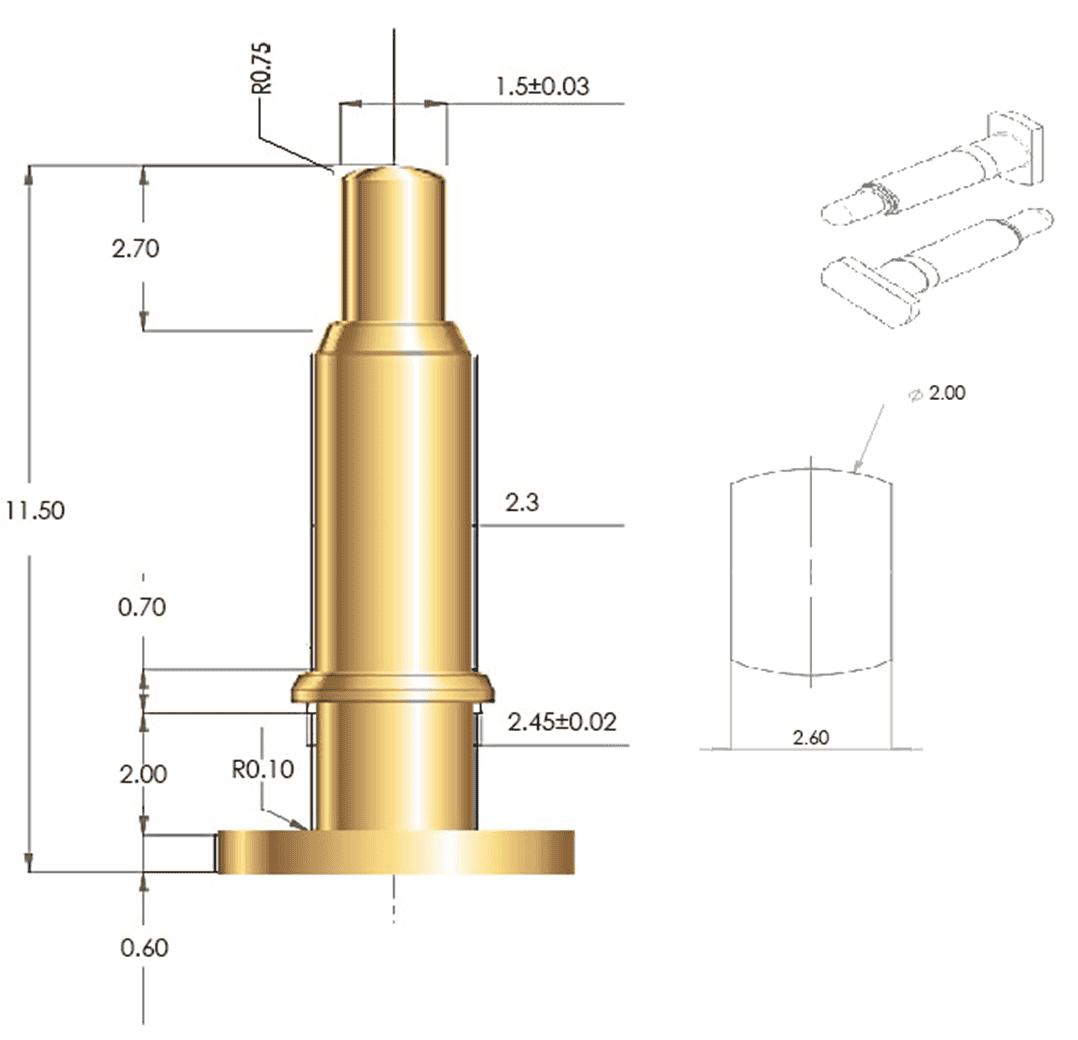

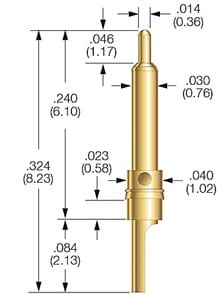

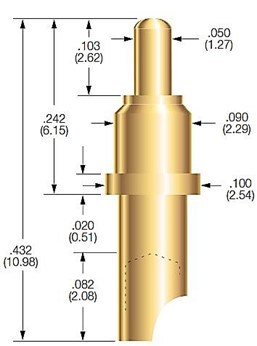

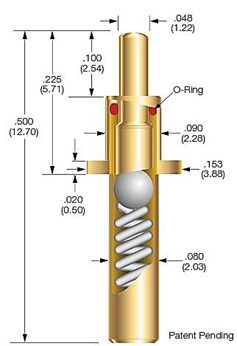

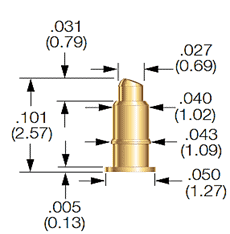

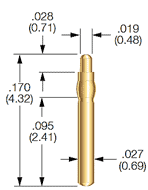

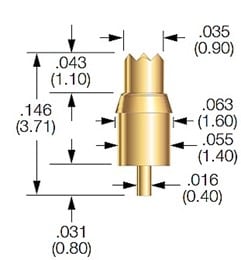

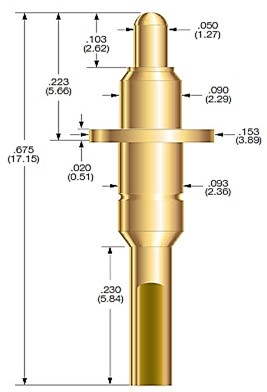

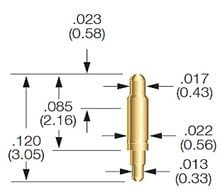

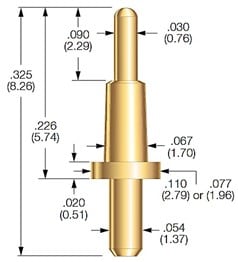

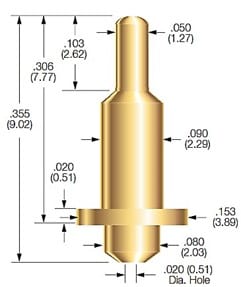

- Mechanical tuning: overall length, travel, working height, head geometry (flat,

crown, concave), pitch, and alignment features to suit your stack-up. - Electrical performance: selectable spring forces and contact designs to meet target

current, low contact resistance, and signal integrity needs. - Materials & plating: high-conductivity alloys with nickel barrier and hard-gold

finishes for durability and corrosion resistance. - Integration support: drawings, samples, and DFM guidance to tailor pogo pins precisely to your enclosure, PCB, and test-fixture constraints.

Applications Across Key Industries

- Semiconductor & electronics test: reliable interfaces for ICT/FCT fixtures, DUT

sockets, and socket systems where repeatable, low-resistance contacts are critical. - Medical & wearables: sealed pogo-pin connectors for hygienic charging and data

links in compact devices and docks. - Industrial & automation: rugged contacts for chargers, docking stations, modular

tooling, and quick blind-mate connections on the factory floor. - Defense & rugged systems: spring-loaded contacts that tolerate shock, vibration, and

frequent maintenance, supporting field-ready modular architectures. - Charging & modular devices (cross-sector): pogo pins simplify hot-swap batteries, cradle charging, and board-to-board links while maintaining long mechanical life.

Admati Agencies – Quality You Can Trust

Since 2007, Admati Agencies has supplied components and sub-systems to leading

organizations, combining technical expertise with dependable delivery. Our quality

assurance team verifies every build with advanced metrology and documented processes,

and our engineering support helps you balance electrical performance, mechanical life, and

cost from prototype to scale. Whether you need a standard catalog part or a custom pogo

pin assembly, our team is ready to help.