Mechanical Catalog

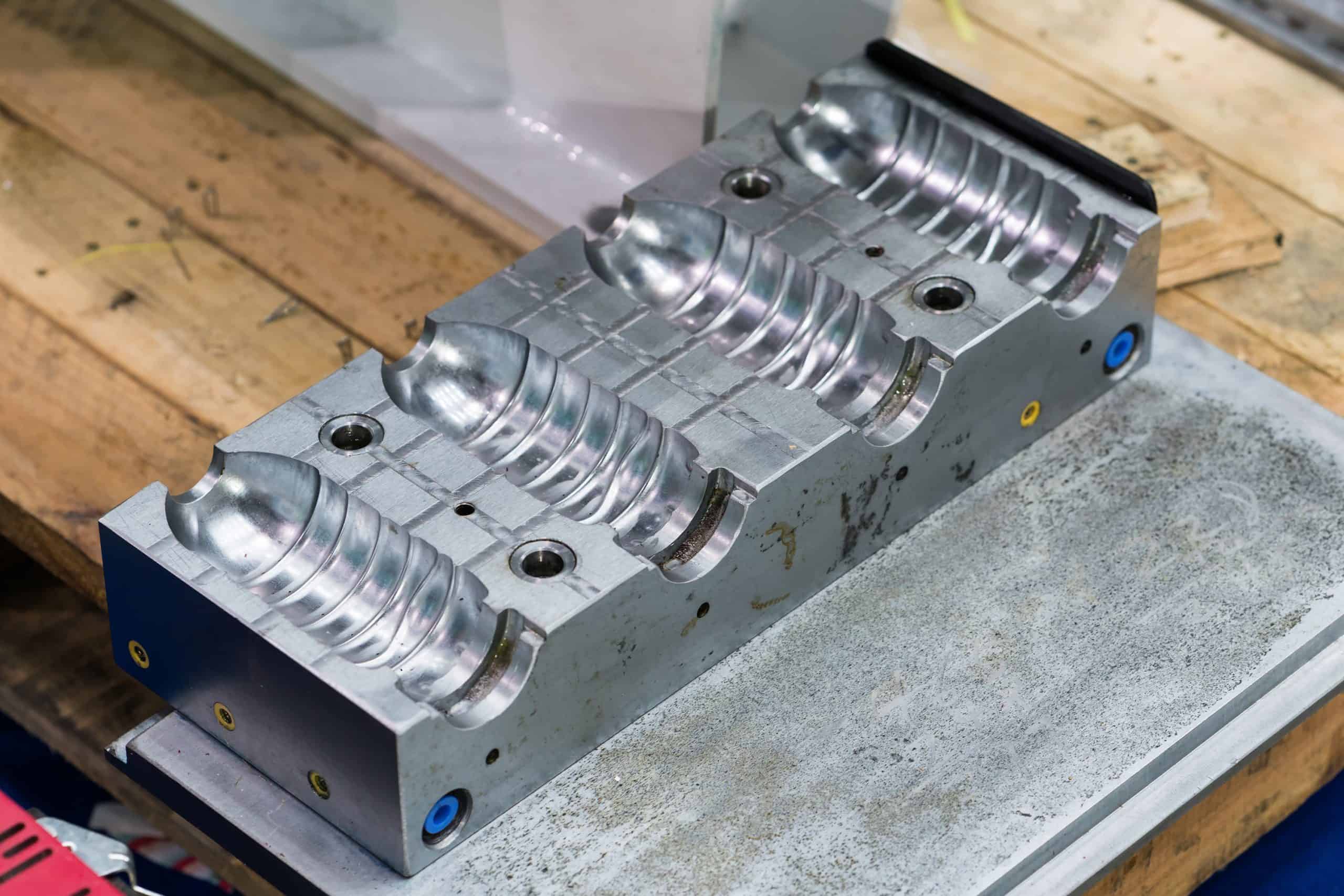

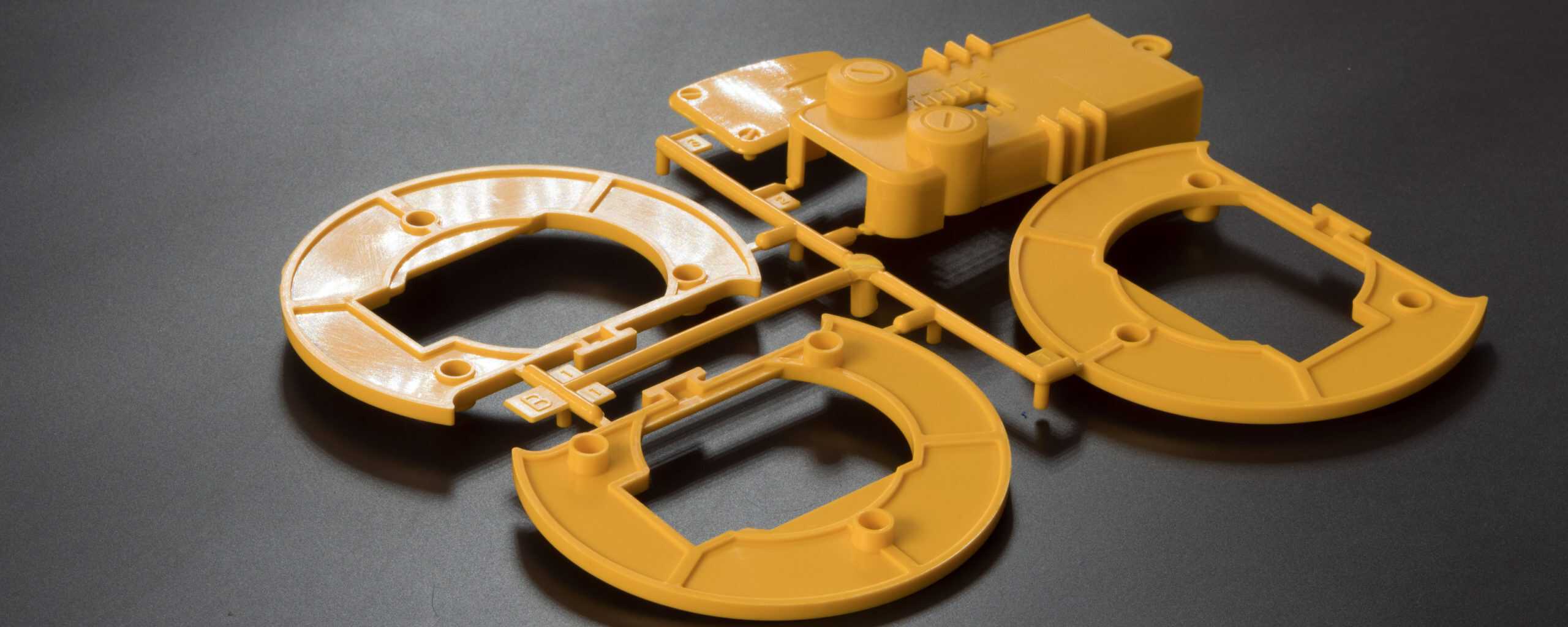

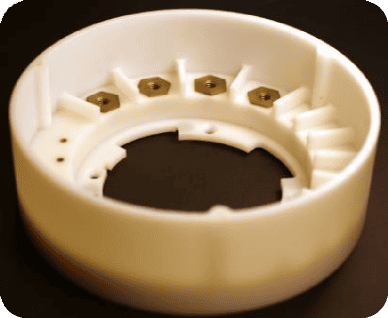

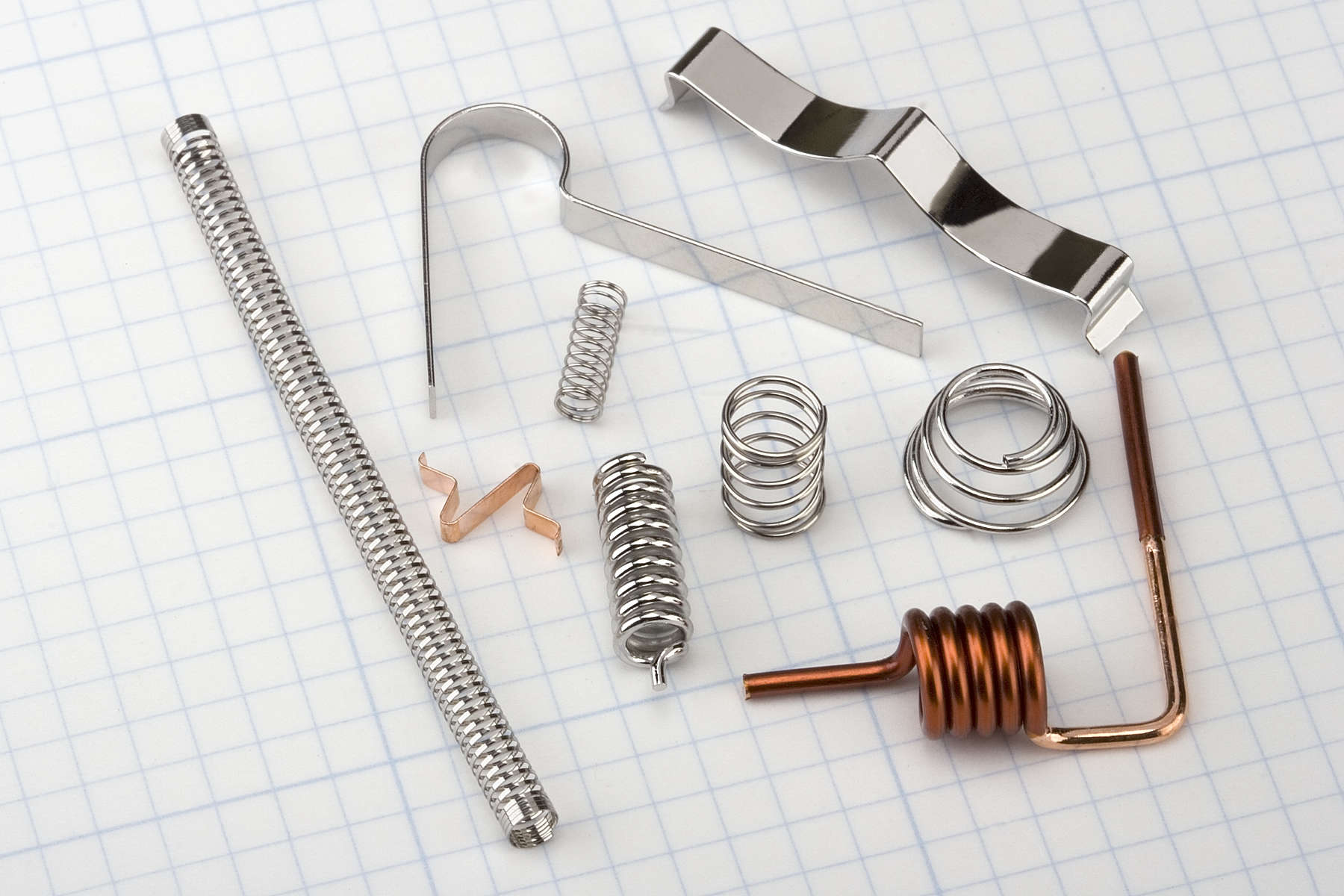

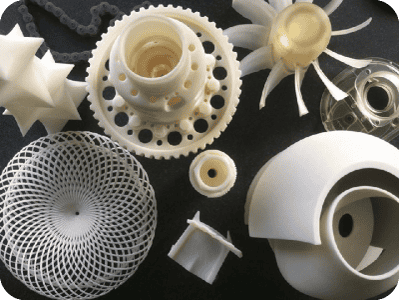

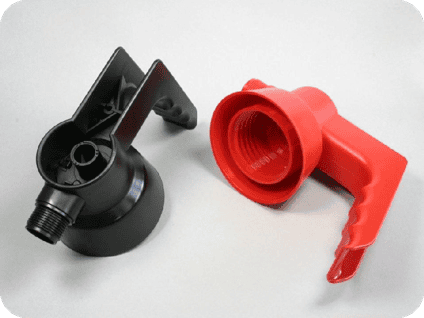

Injection Moulding

Admati Agencies specializes in producing high-quality plastic parts through Injection & Molding, using advanced CNC technology to ensure precise and consistent results. With expertise in overmolding, we offer seamless integration of multiple materials, enhancing product functionality and aesthetics. Our Multicavity Injection capabilities enable high-volume production, meeting your demands efficiently. Moreover, our Silicon Molds service ensures durability and versatility, catering to…

Description

Sizes and weight

How to use

More from the Mechanical Catalog