Mechanical Catalog

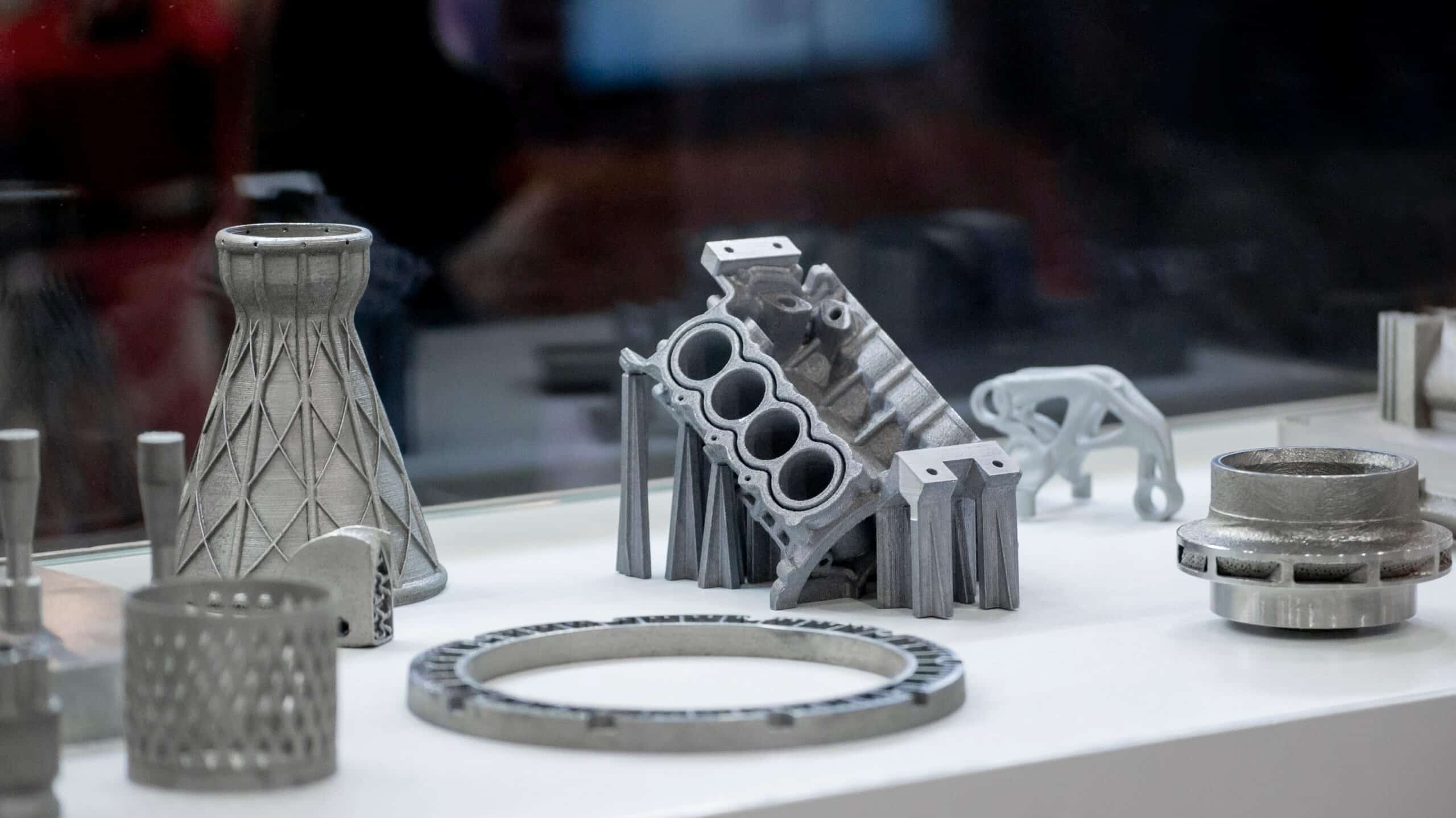

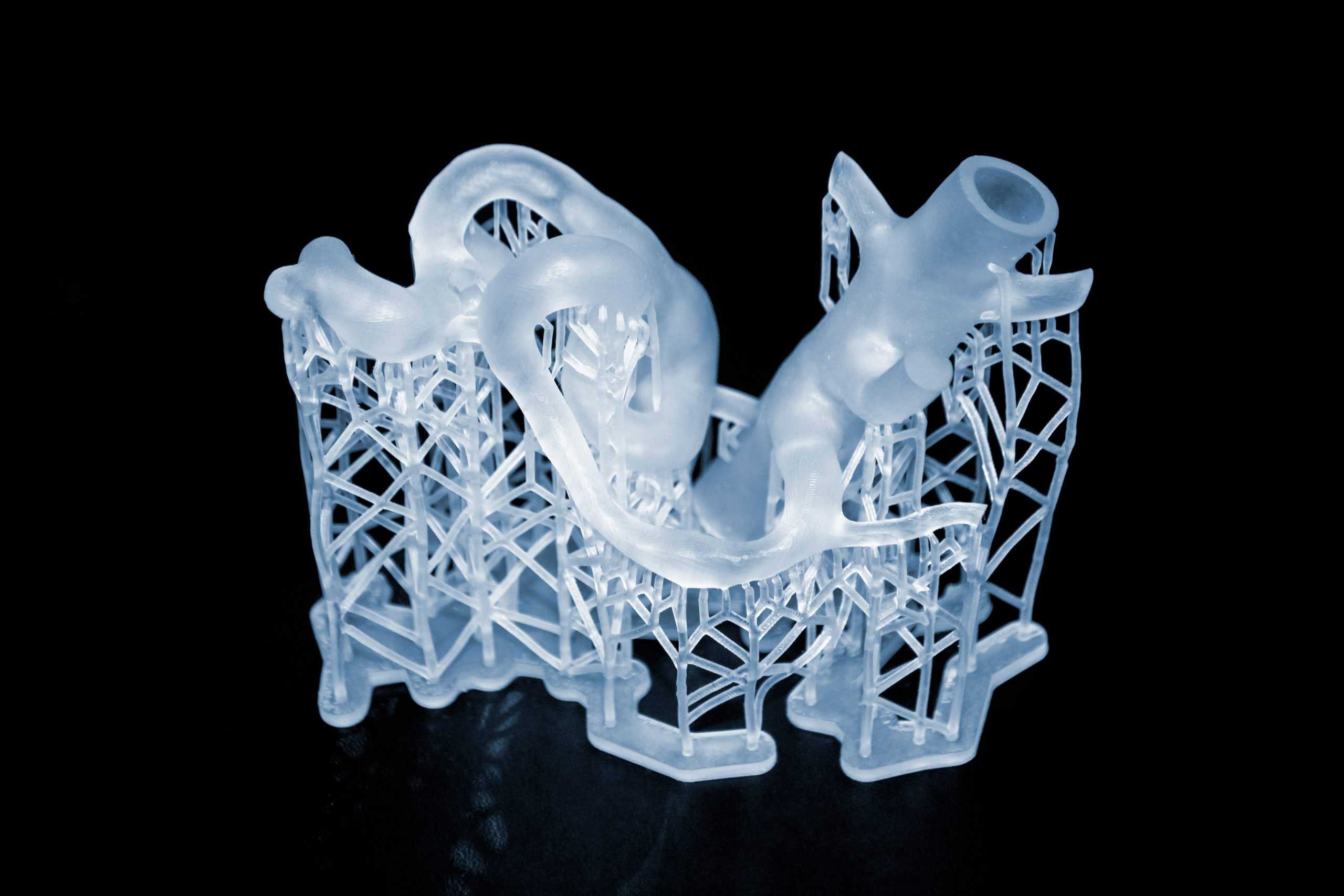

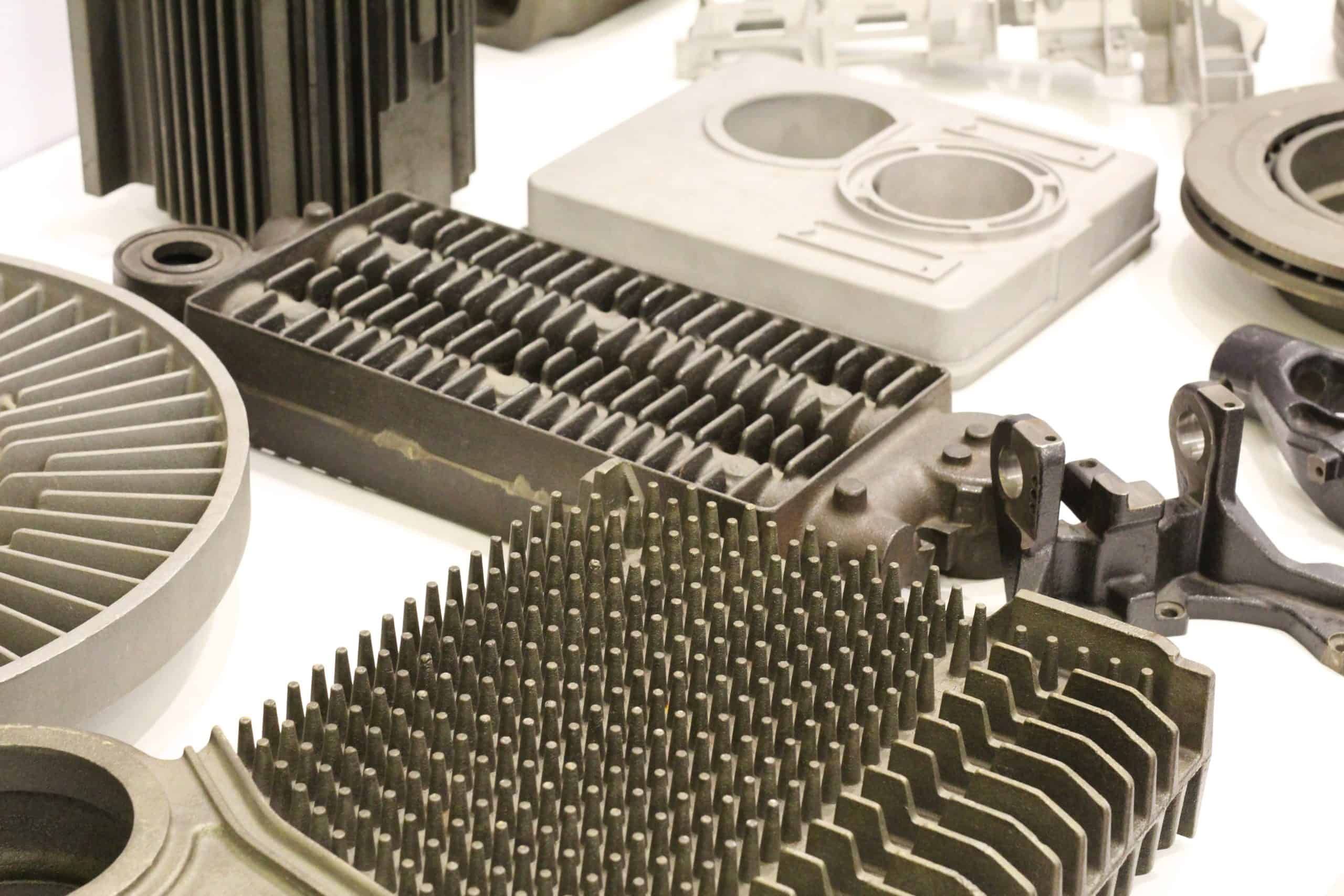

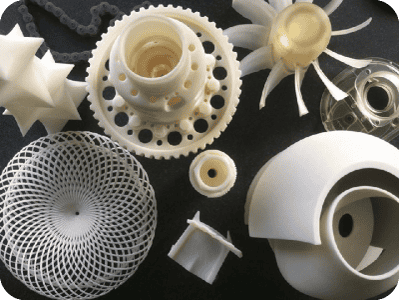

3D printing

Admati Agencies specializes in 3D Rapid Prototyping, employing various techniques such as FDM, SLA, and SLS to bring your concepts to life with unparalleled speed and precision. Our capabilities extend beyond standard printing as we also offer Full Color Printing, enabling vibrant and lifelike creations. Additionally, our Large Parts Printing service caters to projects of a big sizes, pushing the…

Description

Sizes and weight

How to use

More from the Mechanical Catalog