News

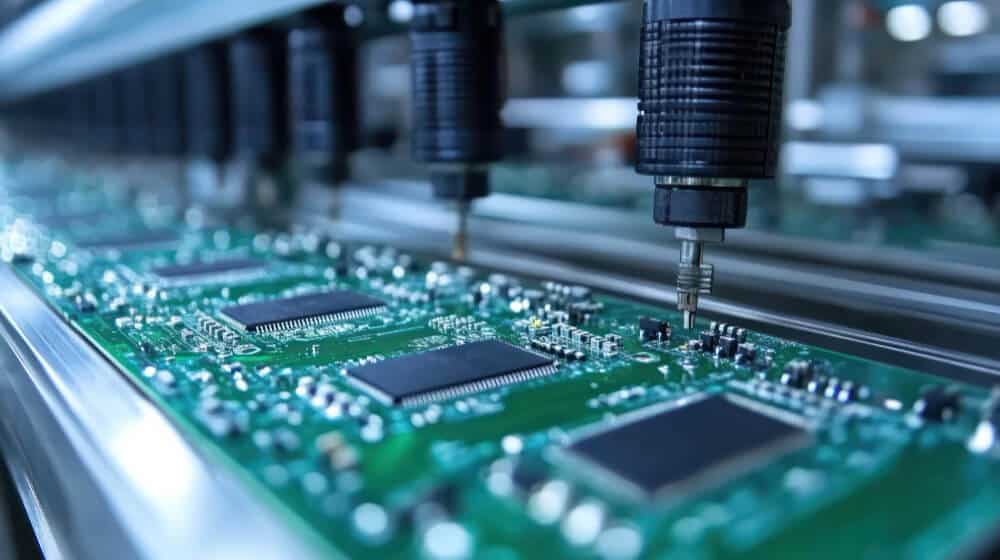

Common Industrial Applications of Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) are a central component in nearly every modern electronic device. They provide a physical and electrical infrastructure for connecting electronic components and enable the flow of electricity and precise control of mechanical and digital operations.

PCBs serve various purposes across different industries—here we present the main ones. We’re here to help you understand just how essential these components are at the core of modern industry.

What Are Printed Circuit Boards?

Printed Circuit Boards are boards made of insulating materials (usually fiberglass) with conductive pathways (such as copper) printed on them. PCBs replace complex wiring and enable easy, compact, and reliable connections between electronic components.

PCBs can be simple (single-layer) or complex (multi-layered) depending on the application. These are the most common types:

- Single-layer PCBs: Used in simple devices like electronic toys, remote controls, and basic household gadgets.

- Double-layer PCBs: Enable routing on both sides of the board to save space and create more efficient current paths.

- Multi-layer PCBs: Contain multiple layers of conductors separated by insulating layers. Designed for advanced systems requiring high performance.

- Flexible PCBs (Flex PCBs): Made from flexible materials that allow bending and use in tight spaces or devices with non-standard shapes.

- Rigid-Flex PCBs: A combination of rigid and flexible boards designed for advanced use in medical, defense, and consumer electronics industries.

Key Industrial Uses of Printed Circuit Boards

1. Consumer Electronics

PCBs are at the heart of every home electronic device—from smartphones, laptops, and tablets to smart home appliances such as smart TVs, refrigerators, and IoT devices.

Advantages of PCBs in consumer electronics include:

- Component miniaturization and compact design.

- Reduced manufacturing costs through high automation.

- Improved reliability and long-term durability.

2. Automotive Industry

The automotive sector heavily relies on PCBs for managing advanced in-vehicle systems, including:

- Engine Control Units (ECUs): For managing fuel consumption, performance, and emissions.

- Advanced safety systems: Such as airbags, autonomous braking, and lane-departure alerts.

- Multimedia and connectivity systems: Touchscreens, smart audio systems, GPS navigation, and vehicle-to-vehicle communication.

- Electric and hybrid vehicles: PCBs play a crucial role in battery systems and energy management.

3. Medical Industry

In the medical field, PCBs are found in critical devices that assist physicians with diagnosis and treatment. Key applications include:

- Medical imaging equipment: MRI, CT, and ultrasound machines rely on PCBs for high-speed data processing and analysis.

- Heart and glucose monitors: Used for continuous patient monitoring in hospitals or at home.

- Advanced surgical equipment: Including surgical robots and precision tools controlled by computer systems.

- Medical implants: Flexible PCBs are found in pacemakers, hearing implants, and neurostimulation systems.

4. Defense and Aerospace Industry

PCBs are a critical component in defense and military systems, where high reliability and durability under extreme conditions are essential. Major applications include:

- Encrypted communication equipment: Advanced military communication systems based on specially designed PCBs resistant to radiation and electromagnetic interference.

- Navigation and radar systems: In military aircraft and advanced radar technologies.

- Satellites and spacecraft: The space industry uses specialized PCBs that can withstand extreme temperature differences and strong vibrations.

5. Industrial Manufacturing and Automation

In industrial automation systems, PCBs are used to control production lines, industrial robots, and smart sensors. These systems include:

- Programmable Logic Controllers (PLCs): For operating industrial machines and processes.

- Smart sensors and control modules: For data monitoring and collection in manufacturing environments.

- Industrial IoT systems (IIoT): Smart machine-to-network connections enable intelligent control, predictive maintenance, and process optimization.

6. Telecommunications and 5G

In the telecommunications industry, PCBs play a central role in high-speed data transmission and advanced wireless communication. As 5G networks evolve, the demand for high-conductivity, high-density PCBs continues to grow. Key applications include:

- Cellular base stations: For converting wireless signals and processing high-speed data.

- Smart antennas and advanced routers: Reliable connectivity, fast data transfer, and reduced network latency.

- Mobile devices and IoT technologies: Rely on compact, low-power, and high-reliability PCBs.

7. Smart Transportation and Railway Systems

PCBs are integrated into modern transportation technologies. They are used for control, safety management, and automation of smart transport systems. Key uses include:

- Railway management systems: For automated control, real-time monitoring, and optimization of train operations.

- Safety and collision prevention sensors: For detecting emergencies and preventing vehicle collisions.

- Smart cards and automated payment systems: PCB-based infrastructure enables efficient operation of public transport networks.

8. Smart Agriculture and Agricultural Automation

In modern agriculture, PCBs are used to improve production efficiency and precise resource management. PCBs are embedded in advanced agricultural systems such as:

- Environmental monitoring sensors: Measure temperature, humidity, and soil pH levels to optimize growing conditions.

- Smart irrigation systems: Deliver precise water flow based on soil and plant needs.

- Agricultural drones and autonomous machinery: For pest detection, field monitoring, and advanced automated farming operations.

Advanced Printed Circuit Boards with Admati Agencies

Admati Agencies is a leader in electronics and PCB solutions, providing advanced services across all industry sectors. The company specializes in the design, production, and distribution of custom PCBs for a wide range of applications, including defense, medical, automotive, and industrial automation.

Our advantages include:

- Comprehensive and professional service: Supporting clients from development to final production.

- Custom-tailored solutions: Rigid, flexible, and multi-layer PCB solutions adapted to specific customer requirements.

- Uncompromising quality: Advanced manufacturing processes, strict quality control, and compliance with stringent international standards.

- Global supplier partnerships: Collaboration with leading manufacturers to deliver high-level innovation.

Whether it’s advanced electronics for medical equipment, navigation systems and smart automotive sensors, or customized defense-grade PCBs—Admati Agencies delivers the best solutions for the industry’s most complex requirements.

For more information and expert consultation, contact us today and benefit from advanced solutions tailored precisely to your needs.

More News Articles