News

How Are Laser Cutting Systems Integrated into Automated Manufacturing Processes?

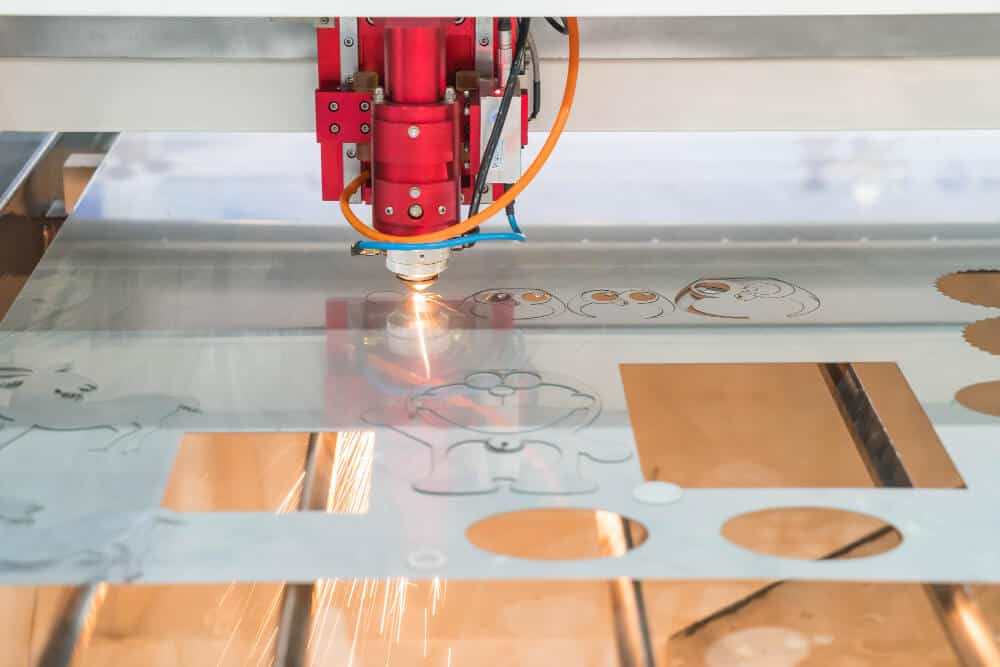

Laser cutting technology is one of the most advanced innovations in industrial manufacturing. Today, many industries incorporate laser cutting systems into automated production processes to improve precision, efficiency, and speed. Integrating these systems into automated production lines requires a deep understanding of the processes, technological adaptation, and organization of the production environment.

This article will explore how laser cutting systems can be integrated into automated manufacturing processes, the significant advantages of laser cutting in industrial automation, and the challenges companies face when implementing this technology into their production lines.

Advantages of Using Laser Cutting Systems in Automated Manufacturing Processes

The integration of laser cutting into automated manufacturing processes offers several key advantages, making it an attractive solution in a wide range of industries.

High Precision and Fast Processing

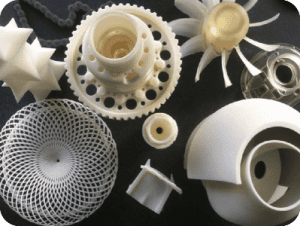

Laser cutting systems provide very high precision, allowing the creation of intricate cuts with fine details in various materials. The ability to control the laser beam in a focused manner makes this technology ideal for processes that require extremely precise cutting, including the production of small and delicate parts.

Additionally, laser cutting operates at high speed, improving production times and enabling industries to significantly increase production rates without compromising product quality.

Flexibility and Material Compatibility

One of the clear advantages of laser cutting is its flexibility and ability to work with a wide range of materials. This technology is suitable for cutting metals such as steel and copper, plastics, wood, glass, and more. This flexibility allows laser systems to be integrated into various industries, from electronics and automotive to textile manufacturing.

Waste Reduction and Resource Efficiency

Laser cutting enables efficient material utilization through precise cutting of raw materials, leading to a significant reduction in waste generated during the production process. This precision contributes to cost savings on raw materials and helps to maintain environmental sustainability. The result is a more cost-effective production process that minimizes waste and reduces overall costs.

Integrating Laser Cutting into Automated Manufacturing Systems

The integration of laser cutting systems into automated manufacturing processes requires precise planning and alignment between the different systems. This requires both technological integration and logistical adjustments to fit the existing production processes.

Designing an Integrated Automated System

The first step in integrating laser cutting into an automated manufacturing process is designing an integrated system. To ensure optimal system operation, the production process must be planned so that it transitions seamlessly between different stages, including feeding raw materials into the machine, transferring them to the laser cutting system, and removing the finished products from the system.

Proper planning should also include integrating robotics systems, which assist in moving raw materials and finished products between machines efficiently. Robots can help with material feeding into the cutting machine and removing the finished materials after cutting.

Incorporating Automated Quality Control

To ensure high product quality, automated quality control systems must be incorporated into the manufacturing process. Advanced laser cutting systems can be equipped with sensors that detect errors or defects during the cutting process. These sensors measure the accuracy of the cut in real-time, allowing for early detection of process issues.

The control system also helps adjust the cutting machine’s parameters, such as beam speed and intensity, based on the material being cut, improving process outcomes and reducing the likelihood of errors.

Managing the System with Software

A crucial part of integrating laser cutting systems into automated manufacturing processes is the use of advanced software for system management and control. These programs allow precise control over cutting parameters, including beam intensity, movement speed, and angle, according to exact production requirements.

Advanced management software also allows for intelligent scheduling of the automated process, ensuring each production stage is appropriately timed. This software can also integrate data analysis and optimization processes for continuous improvement of the production process.

Challenges in Integrating Laser Cutting into Automated Manufacturing Processes

Despite the significant advantages of laser cutting in manufacturing, there are several challenges to consider.

High Initial Costs

The integration of automated laser cutting systems requires a high initial investment. The cost of purchasing laser systems, along with installation and integration into the production line, can be burdensome for some companies, particularly those not engaged in mass production. However, these costs are offset over time by the efficiency and savings the system provides.

Maintenance and Technical Care

Laser cutting systems require regular maintenance and technical care to ensure optimal operation over time. Maintenance includes lens cleaning, precise calibration of the machine, and troubleshooting. Insufficient maintenance can lead to malfunctions, reduce production quality, and cause downtime in automated production lines.

Adaptation to Changing Materials

Although laser cutting systems can work with a wide range of materials, adapting the system to changing material types requires specific parameter adjustments for each material. Frequent changes in material types during the production process can slow down the cutting process and require repeated system adjustments.

Conclusion

Integrating laser cutting systems into automated manufacturing processes offers numerous advantages, including maximum precision, production flexibility, resource efficiency, and waste reduction. Advanced automation processes can incorporate laser technology alongside robotics, management software, and quality control systems to create an efficient and continuous production array. However, there are challenges concerning initial costs, maintenance, and system adaptation to different materials. Ultimately, the proper integration of laser cutting technology into automated manufacturing processes can significantly improve the quality and efficiency of industrial production.

More News Articles