The Importance of Springs in the Medical Industry

Springs are widely used in the medical industry and provide essential functionality in a vast number of devices. They are integral components in surgical instruments, hospital beds, and diagnostic machines — items where precision and reliability are paramount. With high-quality manufacturing, they ensure that medical equipment operates smoothly and efficiently.

Automatic syringes – The spring enables precise and controlled injection of the medication, while maintaining constant pressure throughout the procedure. Proper spring function is essential to prevent incorrect dosage, which could directly affect patient health.

Laparoscopic surgical instruments – Tiny springs are built into the opening, closing, and maneuvering mechanisms of surgical tools. They allow for precise levels of resistance and automatic return of the tool to defined positions, thereby assisting doctors in performing complex actions with maximum safety.

Valves in heart devices – With the integration of springs, it becomes possible to open and close critical valves, regulate continuous pressure, and prevent backflow of blood. Any deviation in spring performance could directly impair heart function.

Ventilation systems – The spring is responsible for the cyclic movement of mechanical parts, such as valves or pistons, and helps maintain an accurate breathing rhythm. Proper function of the component ensures continuous and efficient air supply.

In Which Other Industries Is Spring Manufacturing Common and Important?

Beyond medicine, springs have many other applications, including:

Automotive – Springs are essential for shock absorbers, clutches, and vehicle brakes.

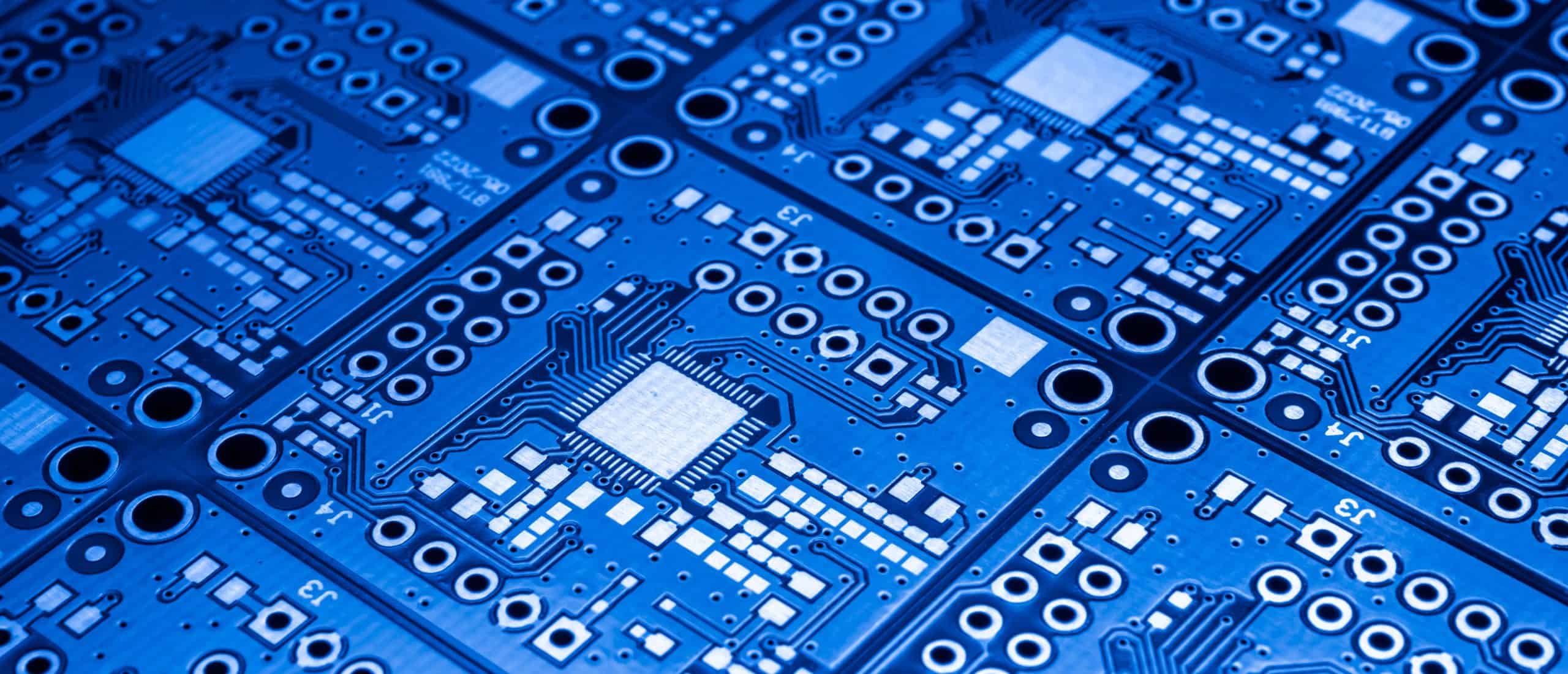

Electronics – Springs are used in the manufacturing of switches and connectors.

Aerospace – Springs are found in control and landing equipment.

Military – Springs are used in weapons and military vehicles.

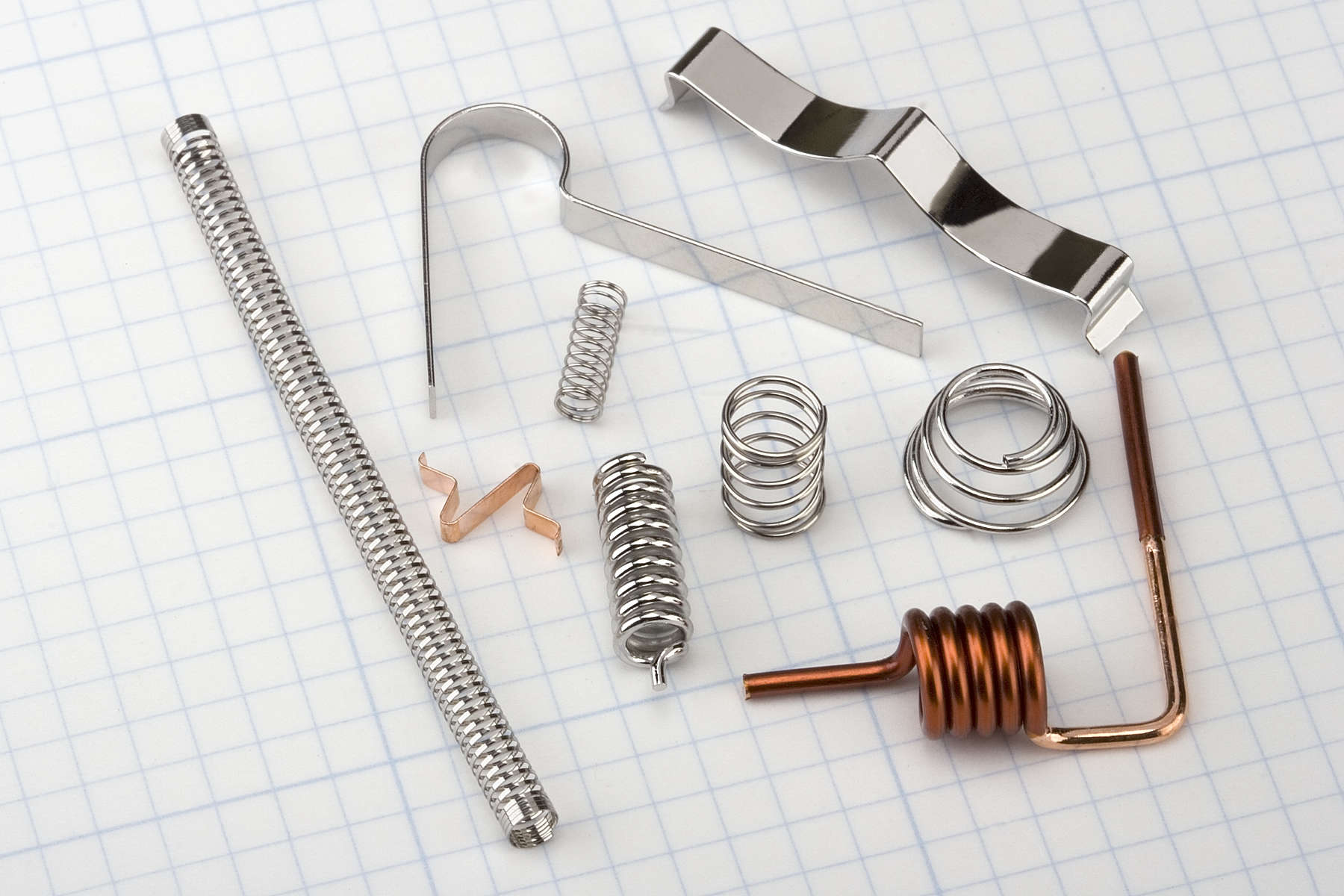

Common Types of Springs – Compression, Extension, and Torsion

Springs come in different forms, each designed for specific applications:

Compression springs – Designed to operate under a load that compresses them, such as in vehicle suspension systems.

Extension springs – Stretch to absorb tension. For example, trampoline springs.

Torsion springs – Apply torque or rotational force, as seen in clothespins and garage doors.

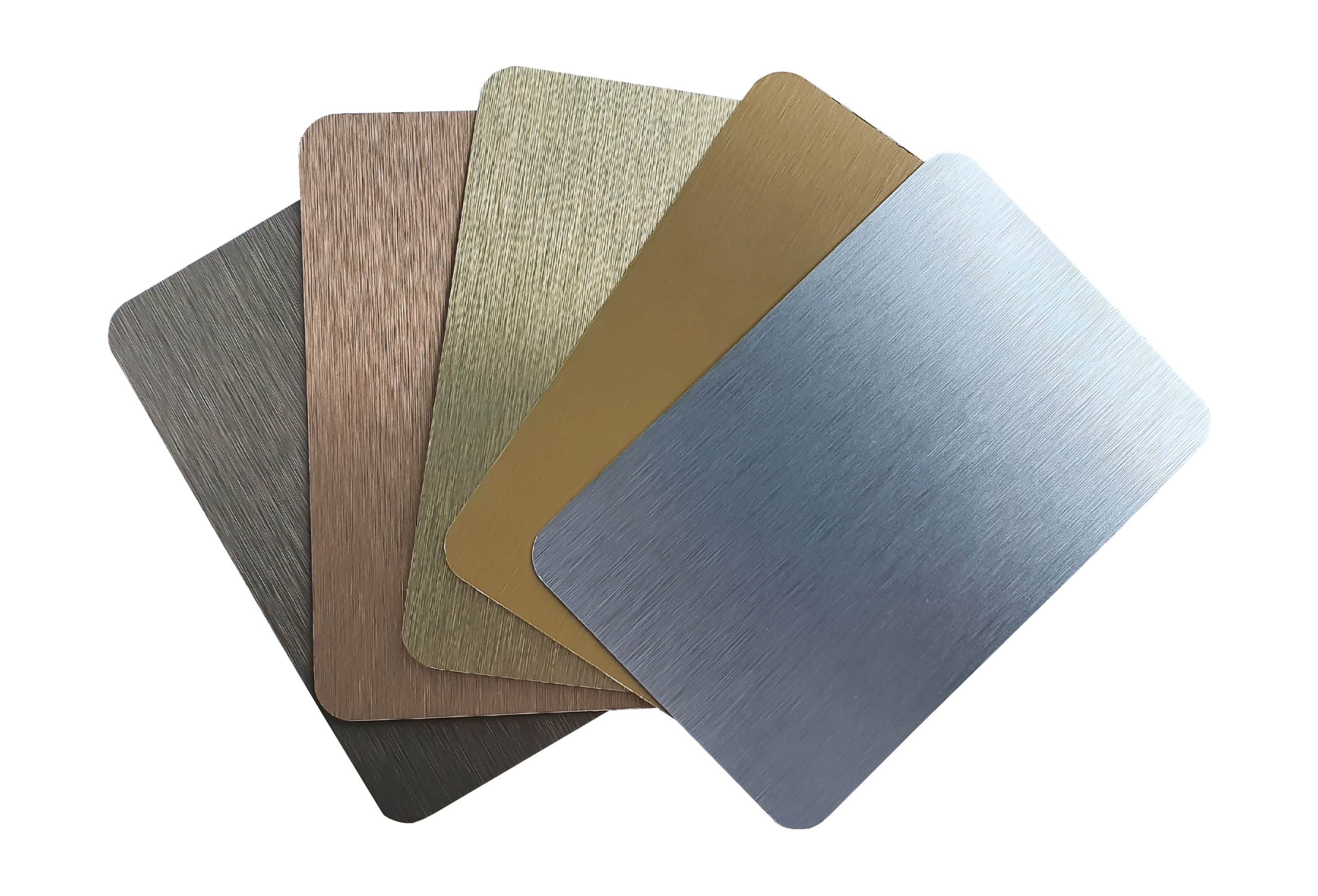

Materials for Medical Springs

Medical springs are manufactured from special materials chosen based on stringent properties to prioritize safety, durability, and precise function. The main materials include:

316L and 304 stainless steel – Considered a medical standard due to high corrosion resistance, compatibility with sterilization processes, and excellent biocompatibility.

Titanium – Very strong, lightweight, does not cause bodily reactions, and suitable for surgical and implant applications.

Nitinol (nickel-titanium) – A smart alloy with “shape memory” properties that allows it to return to its original form after deformation, making it ideal for dynamic mechanisms.

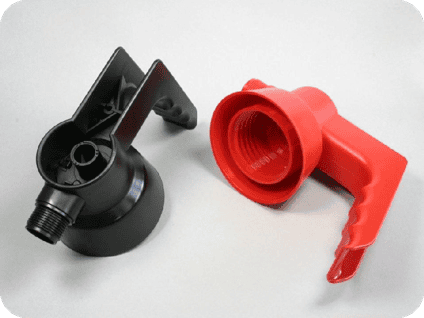

Advanced Manufacturing Capabilities for Precision Springs

Modern manufacturing technologies, as used in our facility, allow for precise production of springs and rely on computer-aided design and automated machines. The result is high-quality and uniform springs that meet strict specifications for a wide range of industrial applications.

Quality Control in Spring Manufacturing

Quality control in the spring production at our facility is rigorous and includes multiple inspection stages to ensure compliance with strict standards. Advanced testing methods, such as load testing and metal fatigue analysis, are applied to ensure optimal durability, performance, functionality, and reliability for the intended application.

Standards and Regulations in the Medical Spring Industry

ISO 13485 defines the requirements for quality management systems for medical devices. Its role is to ensure that every stage of production meets strict regulatory requirements. Alongside it, ISO 9001 refers to general quality management and helps ensure consistency, continuous improvement, and process control.

In addition, FDA regulations for medical devices require full traceability of materials, manufacturing processes, and quality control measures. Adhering to these standards is critical to producing precise, reliable, and safe components — especially when dealing with devices intended for direct contact with the human body or for critical use in hospitals.

How Long Does It Take to Manufacture Springs?

The time required to produce springs can vary significantly depending on complexity and order volume. Simple springs can be manufactured within hours, while the production of more complex or custom-designed springs may take several days or weeks — especially when accounting for planning, prototyping, and testing phases.

Advantages of Working with Admati

Admati brings over 16 years of experience and a portfolio of more than 10,000 different products successfully supplied to over 500 clients. Our advanced manufacturing capabilities, alongside strict quality control and robust engineering infrastructure, allow us to meet even the most stringent client requirements.

Thanks to a combination of advanced technological equipment, high availability, and flexible ordering options, we are able to deliver complex, custom-made medical springs — meeting tight deadlines without compromising performance.