What is Sheet Metal Fabrication?

Sheet metal fabrication is an industrial manufacturing process used to shape flat sheets of metal into complex forms using force and mechanical tools. The designs and final products are suitable for various applications.

Sheet Metal Bending – The Full Work Process

Each stage in the process affects the precision and quality of the next stage, and therefore the work sequence and coordination between all components are of great importance. This is the full process:

Planning and Engineering – Precise definition of project requirements, computerized drawings (CAD), and selection of materials according to the final objective.

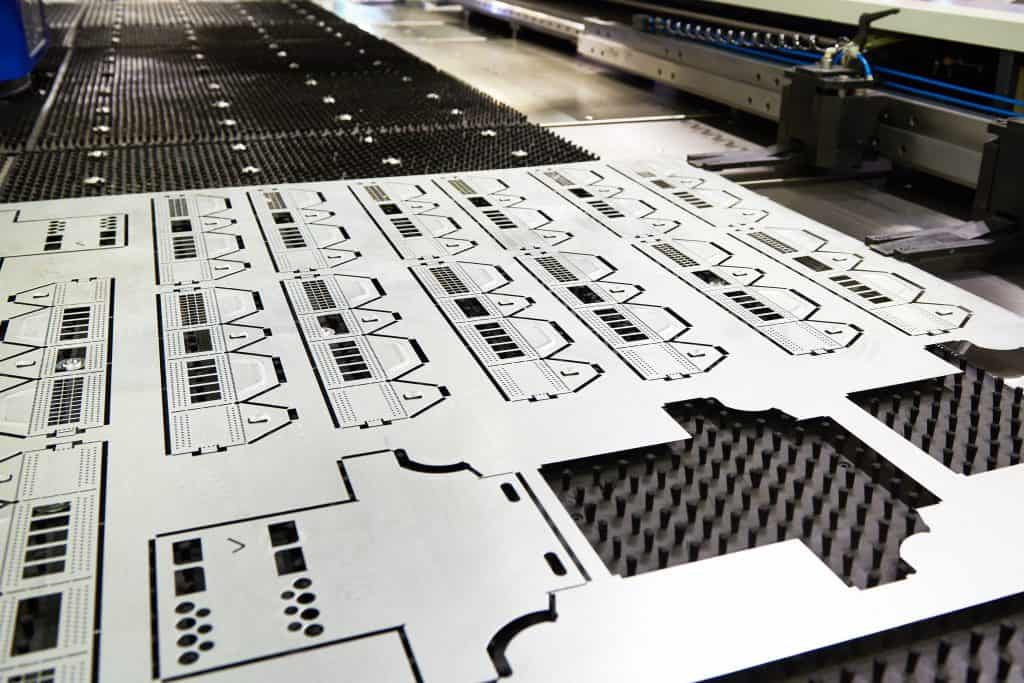

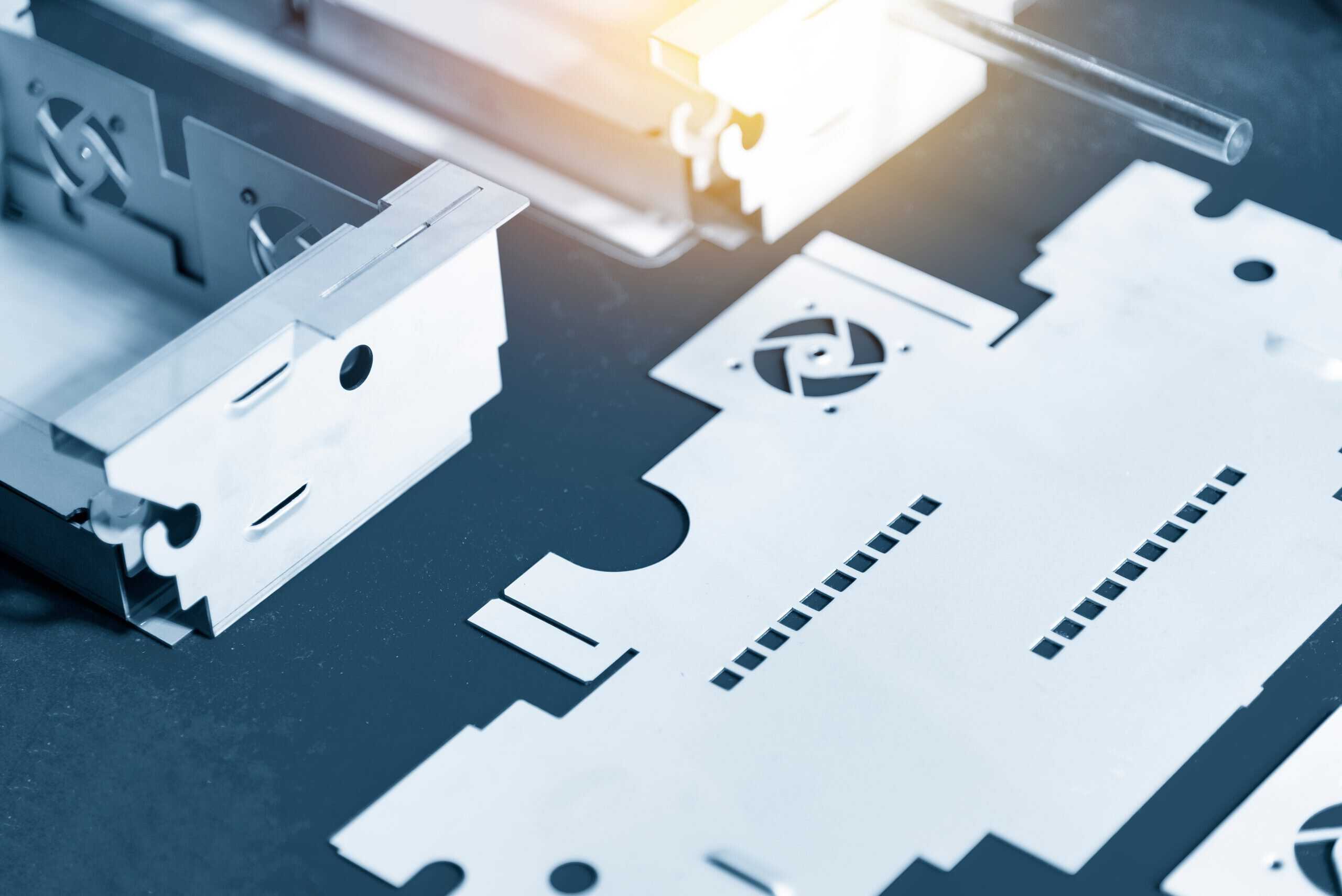

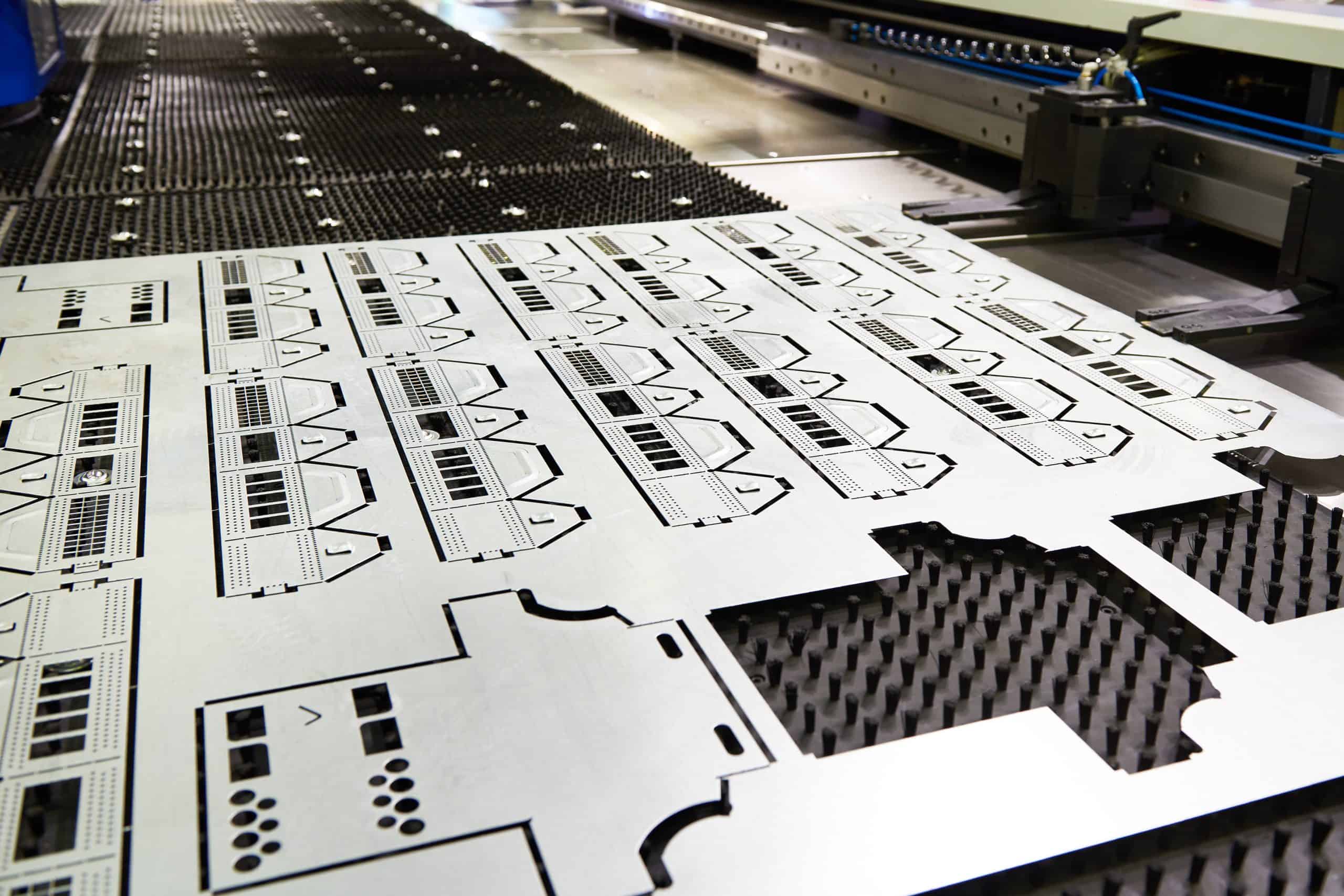

Sheet Cutting – Laser cutting or other technologies, according to the set dimensions and configuration, for accurate preparation before bending.

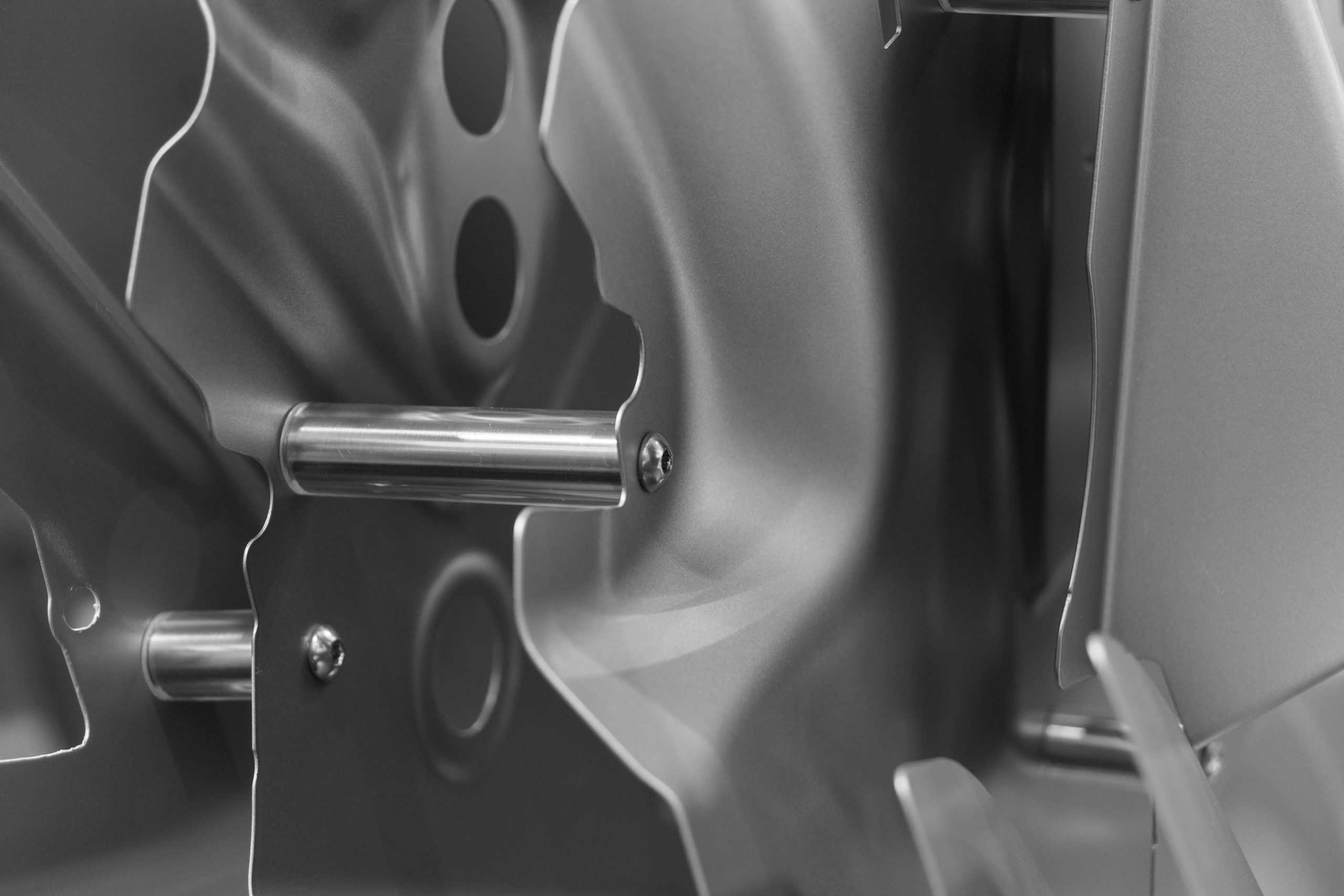

Precise Bending – Performing bends according to specification, using advanced CNC machines, while maintaining uniformity, geometric strength, and maximum accuracy.

Complementary Processing – As needed, the work process also includes welding and assembly, drilling, polishing, or mechanical connections.

Coating and Painting – A finishing stage to improve resistance to corrosion and to create a professional and ready-to-use appearance.

Quality Control – Final inspections to ensure full compliance with specification and standards.

Different Types of Sheet Metal Fabrication – Machines and Capabilities

There are a variety of machines that enable sheet metal fabrication, including press brakes, bending machines, and panel forming devices. These tools offer capabilities ranging from simple bends to complex configurations, providing precision and customization for a wide range of purposes. Each type of machine supports specific materials and thicknesses.

Common Applications of Sheet Metal Fabrication

Sheet metal fabrication is integral to many industries, including:

- Military: Developing armored vehicles and other defense equipment.

- Medical: Constructing components for medical devices and hospital equipment.

- Aerospace: Creating frames and wing components.

- Automotive: Manufacturing chassis and frames.

- Construction: Designing roofing panels and architectural elements.

- Electronics: Developing parts for refrigerators, washing machines, etc.

Advantages of CNC Sheet Metal Bending

Using CNC technology in sheet metal bending not only increases the level of accuracy but also streamlines the entire process both technically and economically. The main advantages include:

Time Saving – Computerized bending enables fast processing of parts, without the need for manual adjustments between pieces.

Maximum Accuracy – The system is controlled by a computer and produces uniform results, even in large and complex projects.

Error Reduction – Automation reduces the risk of deviations from the plan or recurring defects.

Economic Feasibility – Less material waste and need for repeated repairs, alongside lower production costs.

Consistent and Reliable Result – Which enables meeting tight deadlines and performing rigorous quality control.

Client Advantage – Thanks to high efficiency, it is possible to offer faster service at a competitive price without compromising on quality.

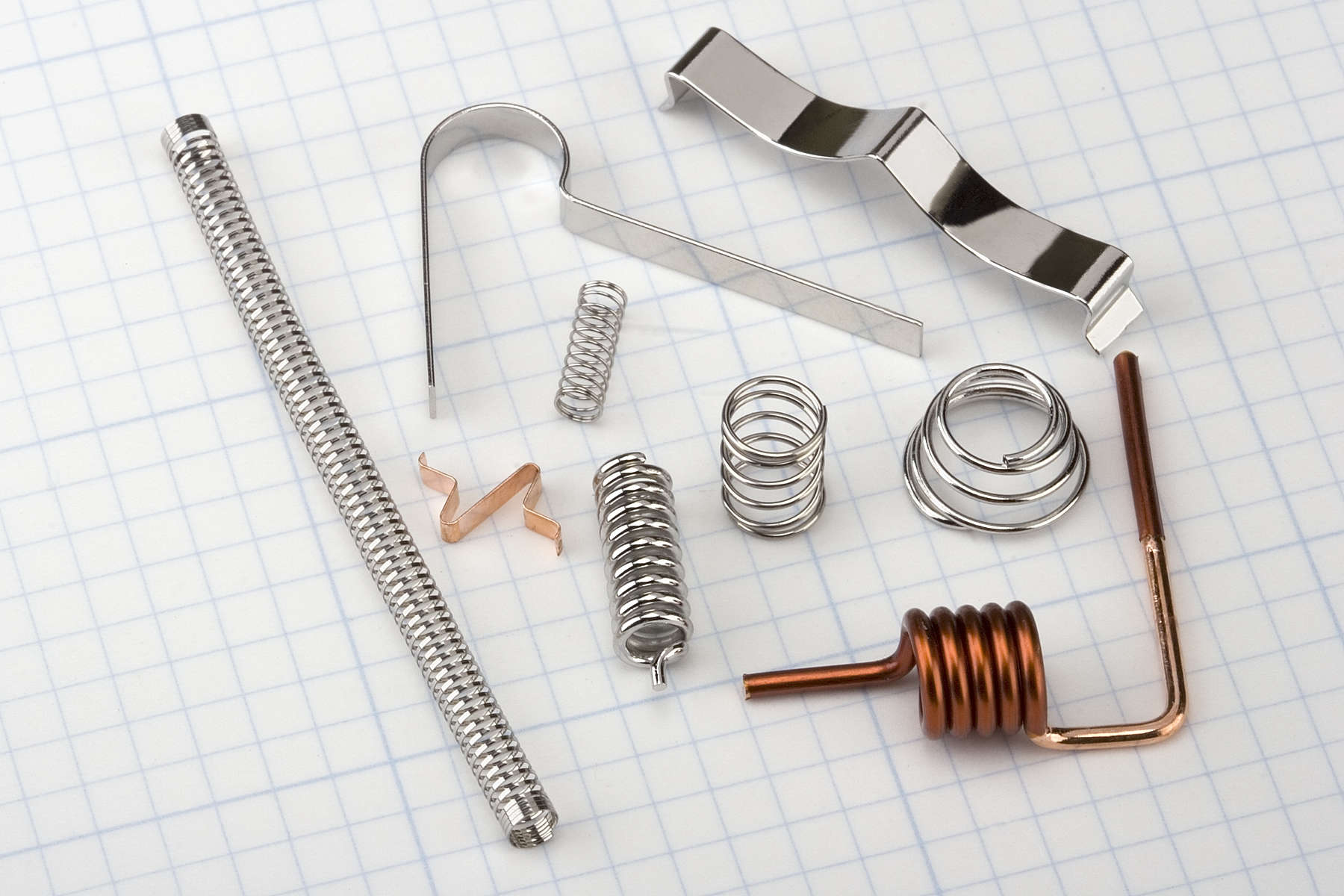

Materials That Can Be Shaped Using Professional Sheet Metal Fabrication Machines

Professional sheet metal fabrication machines can shape a variety of materials, including aluminum, stainless steel, copper, brass, and titanium. Each material’s properties dictate the specific techniques and settings required for optimal fabrication results.

What Level of Precision Can Be Achieved in Sheet Metal Fabrication Processes?

Sheet metal fabrication processes can achieve very high levels of precision. Advanced machines are computer-controlled to ensure accuracy and allow for repeatable designs for mass production, essential for industries requiring precise specifications.

Customized Solutions with Sheet Metal Fabrication Machines

Sheet metal fabrication machines offer customized solutions by adapting to specific project requirements. This flexibility allows for unique profiles and complex geometries, tailored to client needs in various industries. Through advanced settings and automated controls, the machines can deliver highly accurate results.

Why Choose Admati?

At Admati, sheet metal bending is performed in a complete production system managed meticulously. The company works with industries that require exceptionally high precision, bringing with it accumulated years of experience in working with complex engineering specifications.

The combination of advanced equipment, high availability of raw materials, and rapid response capability allows Adamatech to accompany projects from the planning stage to final production, even under tight schedules.

Every operation is carried out with strict adherence to quality control and international certifications, to ensure that the result meets every functional, technical, and aesthetic requirement.