What is Machining?

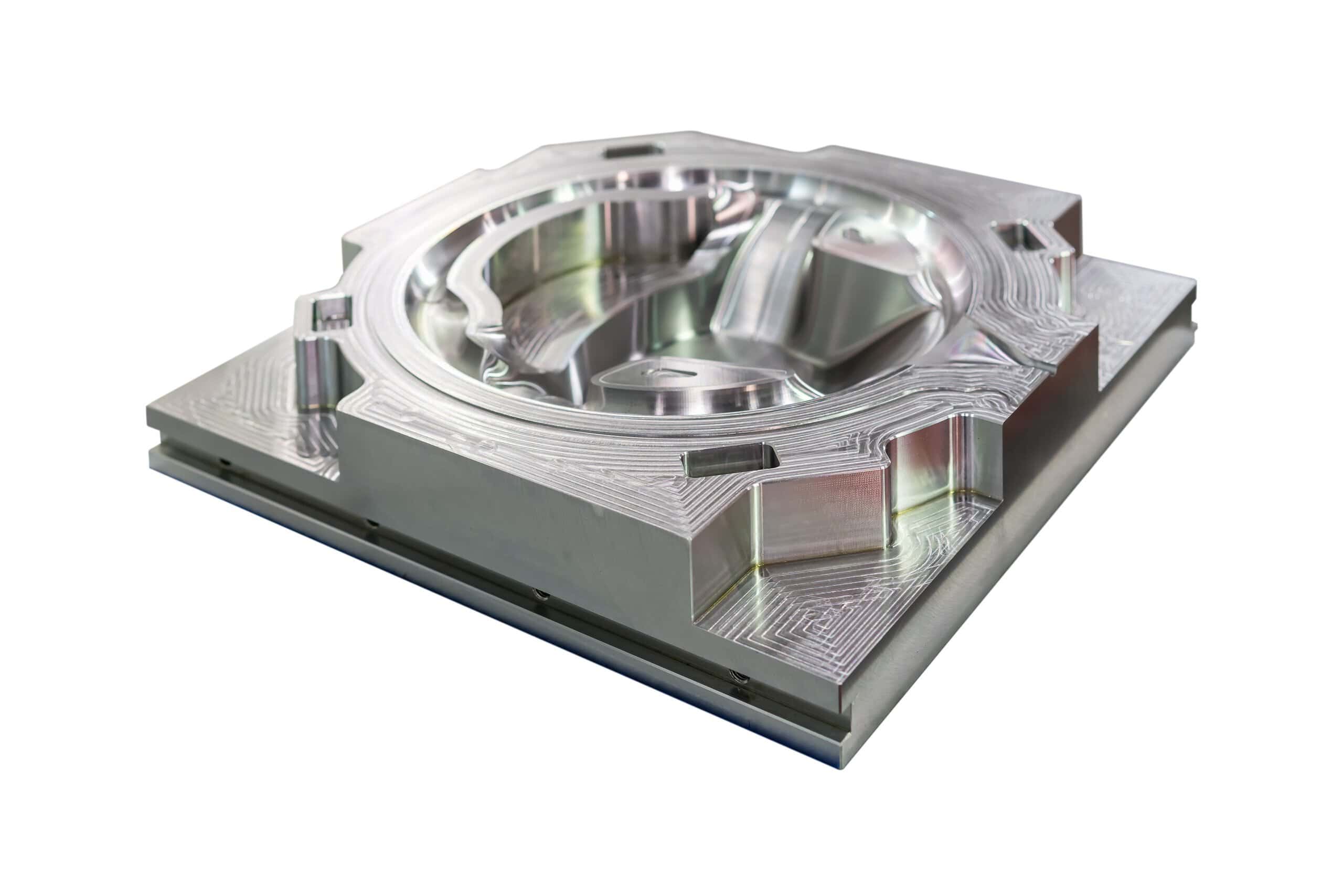

Machining is a manufacturing process that involves shaping metal, plastic, or other materials by removing material using cutting tools to create the desired shape. During this process, the removed material is referred to as “chips.” Machining is typically performed on machines such as lathes, saws, drills, mills, and grinding machines, and can include methods like turning, drilling, milling, and grinding.

The goal of machining is to achieve the desired dimensions, shape, and surface finish of the workpiece, while cutting tools remove material in a controlled manner. This process can be performed manually or through computer numerical control (CNC), which allows for higher precision, efficiency, and repeatability.

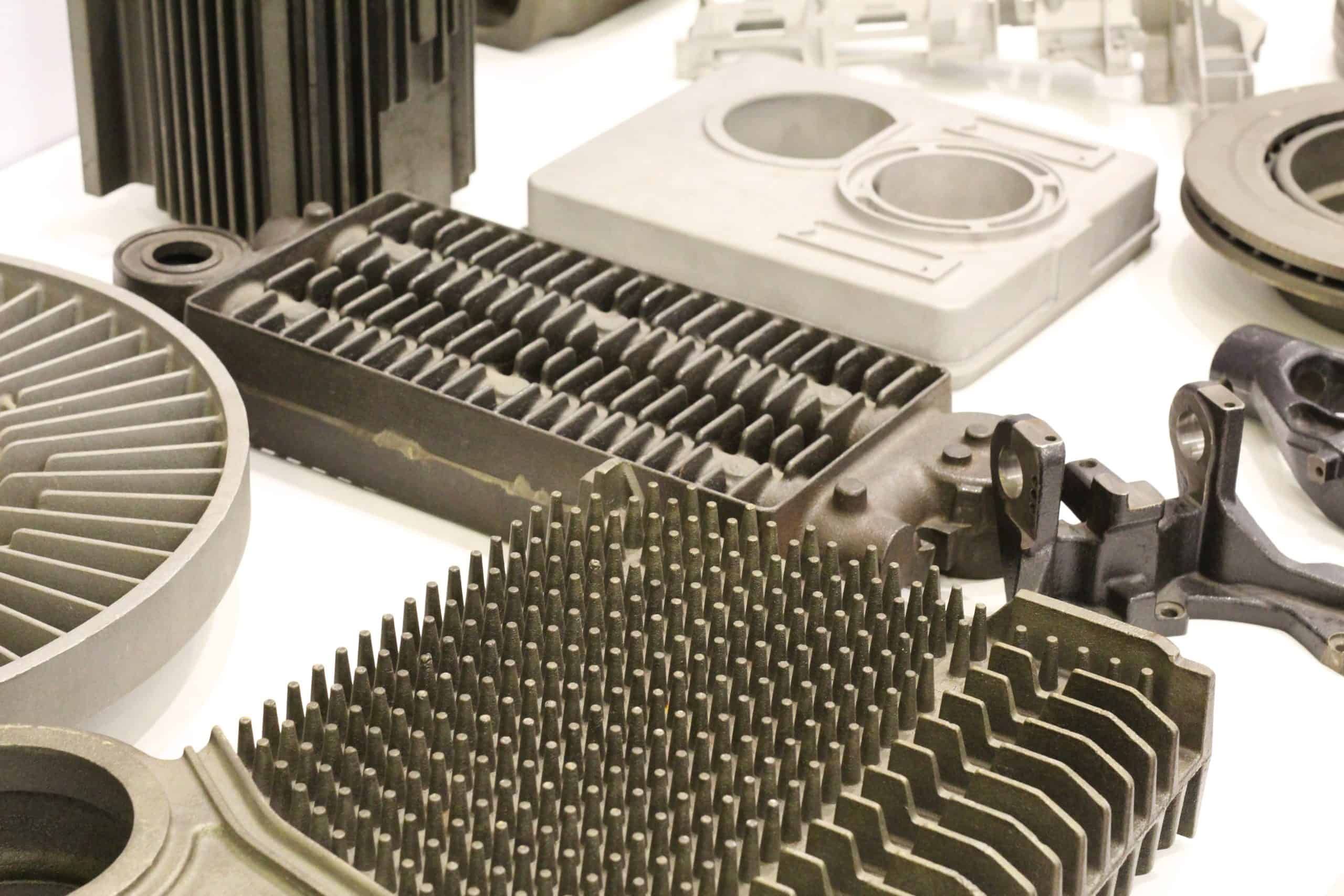

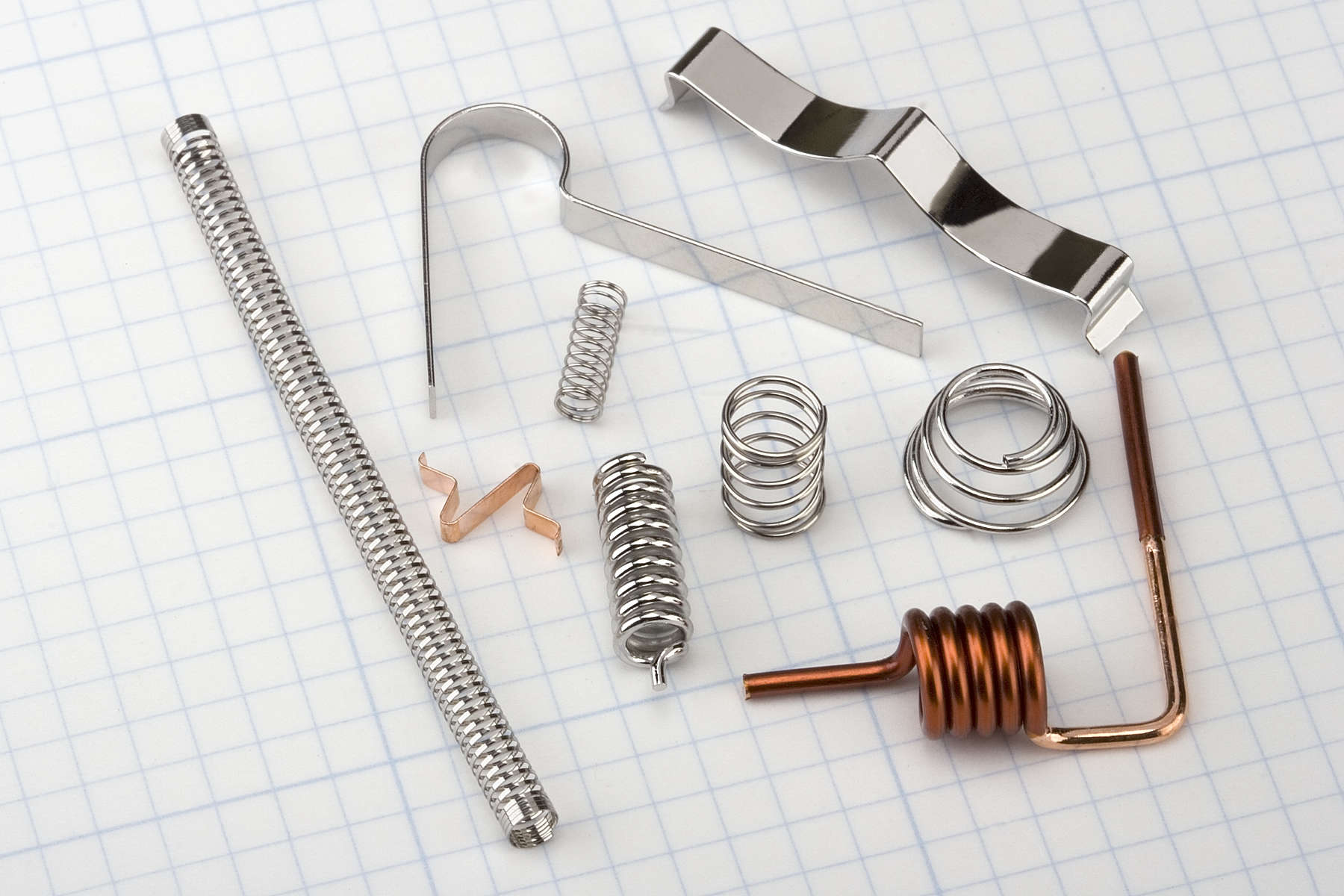

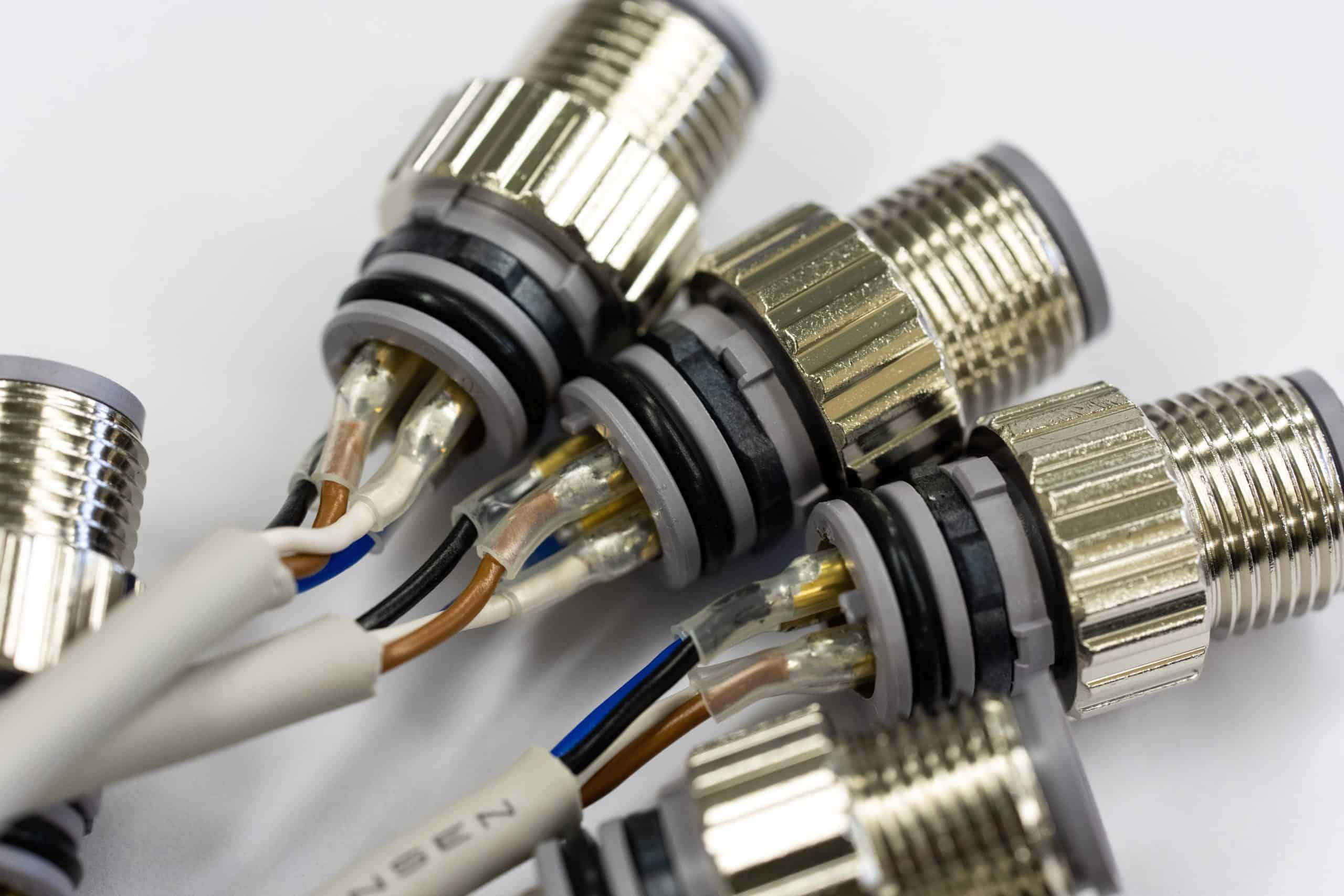

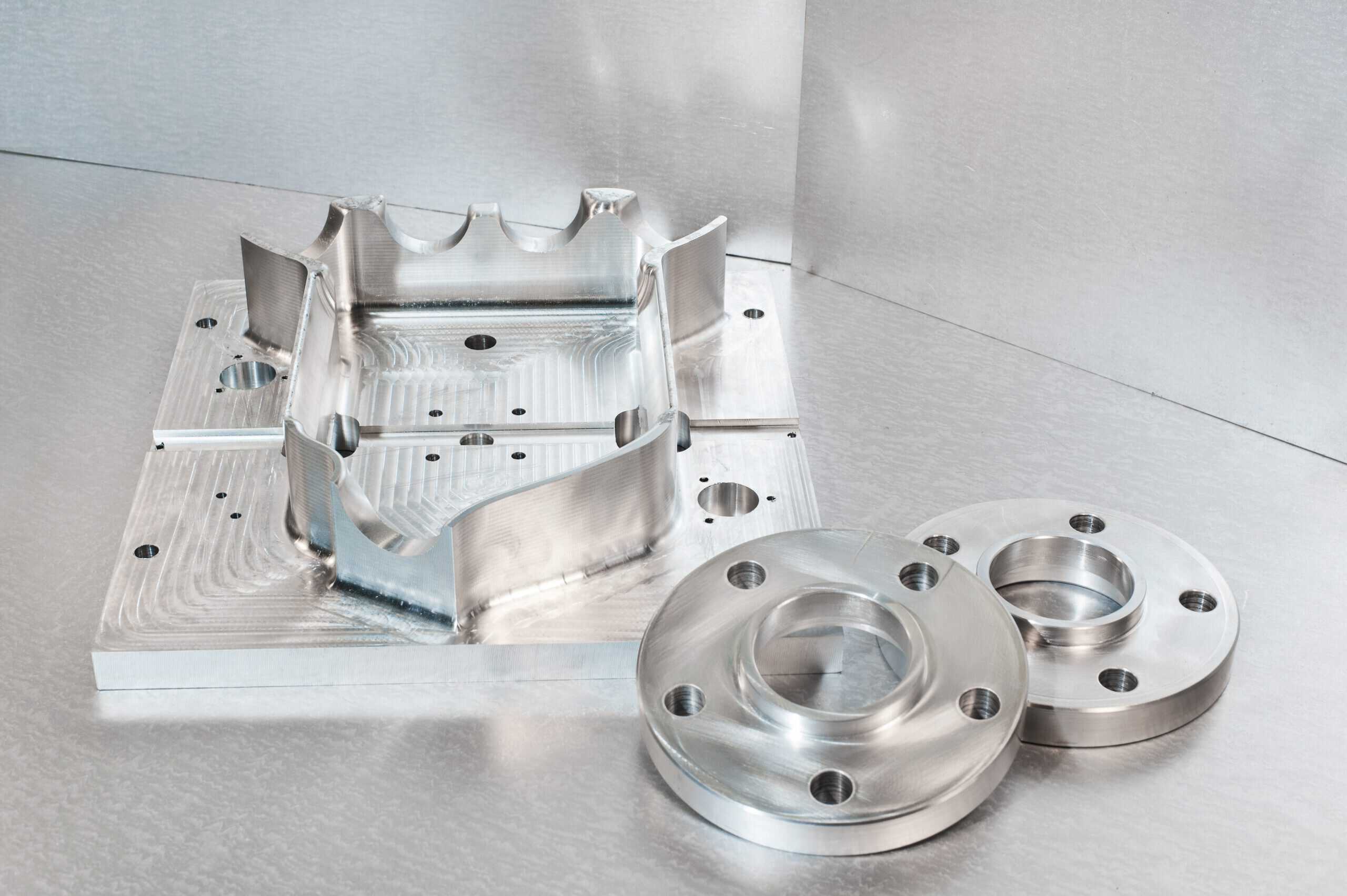

Machining is used in various industries to create precise and complex parts, such as machine components, electronic parts, aircraft components, and more. The choice of cutting material, type of machine, and technique depends on the type of material being worked on, the desired shape, and the modeling requirements of the final part.

What is CNC Machining?

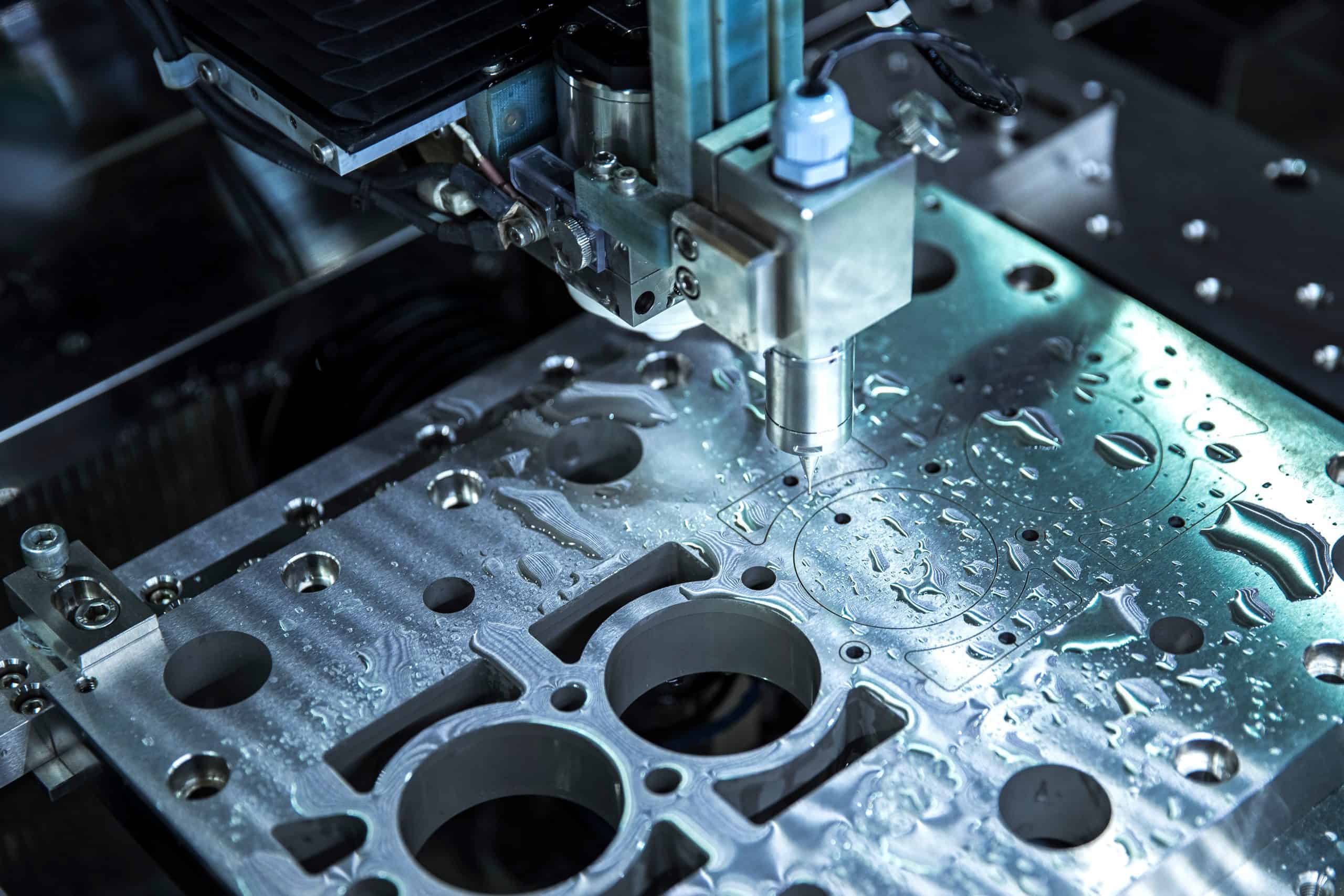

CNC (Computer Numerical Control) machining is an automated method of machining where a computer controls the movement and operation of the machines. This allows for high precision and efficiency in the production of complex parts.

Main CNC Machining Techniques

The main techniques in CNC machining include:

- Turning: In this technique, the workpiece rotates rapidly around its axis, while a cutting tool removes chips to create a precise geometric shape.

- Milling: In milling, a rotating cutting tool removes chips from a stationary workpiece, creating surfaces in various shapes and sizes.

- Drilling: This process uses a drill to create holes in the material by rotating and inserting the cutting tool into the workpiece.

- Grinding: Using a grinding wheel to smooth and refine the surface of the workpiece, typically performed after other machining processes to achieve a high-quality finish.

Each of these techniques offers great flexibility in designing and manufacturing precise and complex mechanical parts using CNC systems.

Materials Used in Machining

A wide range of materials can be used in machining, including metals such as steel, aluminum, copper, and titanium, as well as plastics, wood, and composite materials.

When is CNC machining recommended?

CNC technology is recommended when high precision, consistency, and repeatability are essential, especially in the production of complex parts. CNC machines can replicate intricate parts with great accuracy, making them ideal for mass production. Additionally, they offer design flexibility, as they can be programmed to create complex shapes that are difficult or impossible to achieve with manual machines. Another advantage is the ability to work with a wide range of materials, allowing customization to meet the specific needs of each project.

Types of CNC machining

Turning Machines: Used for removing material from a rotating workpiece to create symmetrical components around an axis, such as cylinders. Milling Machines: Enable cutting and removing material from a workpiece using rotating cutting tools, ideal for creating complex and precise shapes. Grinding Machines: Used to achieve a smooth and precise surface finish on a workpiece by removing thin layers of material. Laser/Plasma/Water Cutting Machines: Utilize various technologies for precise material cutting, depending on the material type and the project’s specific requirements. EDM (Electrical Discharge Machines): Used for processing particularly hard materials or creating complex shapes through electrical discharge.

CNC Machining Services at Admati Agencies

At Admati, we offer advanced CNC machining services, ensuring maximum precision and high efficiency in the production of complex parts. We specialize in custom components, utilizing cutting-edge technologies that allow design and execution flexibility. Admati’s commitment to quality is reflected in our stringent quality control processes, ensuring that every product meets the highest standards.