News

Plastic Parts Manufacturing: The Complete Guide

As everyone knows, plastic is a very central material in modern industry. Almost all finished products, in all fields, contain at least a small percentage of plastic, from tiny electronic connectors to complex packaging for medical equipment and automotive components.

Plastic parts are lightweight, durable, customizable, and inexpensive. To manufacture them requires a precise process and a combination of chemistry, materials engineering, and advanced manufacturing technologies.

The Process of Plastic Parts Manufacturing

First, an informed selection of the raw material must be made. Parts can be manufactured from common thermoplastics such as ABS, polycarbonate, nylon, or polypropylene, or alternatively from more advanced engineering materials.

Each polymer has different characteristics in terms of melting temperature, strength, flexibility, and chemical resistance. Therefore, it is important to choose the material according to product requirements, field operating conditions, and relevant regulations.

After selecting the material, the part and the mold that will be used to manufacture it are designed. The material usually comes in the form of granules, undergoes a melting process in a dedicated machine, is injected or compressed into a mold, cools, and takes on its final shape. Additional finishing stages such as cutting, painting, or printing are usually performed until a component ready for integration into the assembly line is obtained.

Industrial plastic manufacturing is a multi-stage, controlled, and documented process. Each stage, from design to packaging, is predefined and relies on clear quality and control procedures, to produce consistently and reliably in small or large batches.

Work Stages – From Design to Manufacturing

The main stages in the process:

- Engineering design: Defining functional requirements, material selection, geometry and tolerance design in CAD software, adapting the design to manufacturing conditions.

- Mold development: Design and manufacture of a precise metal mold, usually using CNC machining so that the same geometry can be reproduced thousands of times.

- Choosing the appropriate technology: According to material requirements and quantities, plastic injection, compression, blow molding, vacuum, or 3D printing is performed.

- Quality control: Control includes measurements, mechanical tests, and visual inspections throughout the process, to ensure that production aligns with the drawing and defined standards.

- Packaging and logistics: Protecting parts from damage, marking and tracking, preparation for integration into assembly lines or shipping to the end customer.

Key Technologies in Plastic Parts Manufacturing

The factors that determine which manufacturing technology is used are the type of material, design complexity, required quantities, and level of precision. Sometimes several techniques are combined in the same project.

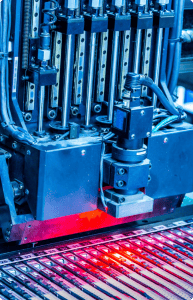

Plastic Injection

Plastic injection is the most common method for manufacturing complex parts in medium and large batches. Plastic granules are heated in an injection machine until melting, and then injected under high pressure into a closed mold. The plastic fills all cavities, cools, and is removed from the mold as a finished part. This technique is suitable for manufacturing parts with fine details, thin walls, and complex geometries, and provides very high consistency over time.

Plastic Compression

The compression process is suitable for thermosetting materials or rubber. The raw material is placed in a heated mold, and after closing it, pressure is applied that forces the material to spread and fill the shape. After the material hardens, a rigid and heat-resistant part is created. This is a suitable method for parts with relatively large thickness, or products where particularly high thermal resistance is required.

Plastic Blow Molding

Plastic blow molding is used to manufacture hollow bodies such as bottles, containers, and cylinders. Plastic is melted and the liquid is introduced into a tube, then air is blown against the mold walls in a way that causes the material to shape like the tube lip. After cooling, a relatively light and strong part is obtained that is cost-effective to manufacture in large quantities.

Vacuum (Thermoforming)

A process performed by heating a flat plastic sheet until it becomes soft, stretching it over a mold, and vacuuming the air from underneath. The pressure differential causes the sheet to adhere to the mold walls and take on its shape. The method is suitable for manufacturing packaging, trays, covers, and relatively shallow bodies, and excels in efficiency for small and medium batches.

3D Printing

3D printing provides a flexible and fast solution for manufacturing prototypes, custom parts, and limited batches. A printer creates the component by adding layer after layer of material according to digital definition. The technology allows manufacturing shapes that are not always possible with a traditional mold, and greatly shortens the time to produce a physical part that can be tested and assembled.

Custom Adaptation According to Customer and Industry Needs

One of the great advantages of plastic is the ability to design it for almost any need, from tiny parts for electronic devices to large packaging for agricultural or medical equipment.

Already at the design stage, raw material can be selected to be rigid or flexible, transparent or opaque, resistant to heat, chemicals, or UV radiation, according to the work environment and requirements.

Different raw materials can also be combined to design a precise solution for each application. Custom adaptation is especially important in demanding industries, where any deviation in the smallest component can affect the performance of the entire system.

Main Areas of Use for Plastic Parts

As mentioned, plastic parts are found in almost every industrial field, whether they are visible to the eye or hidden inside closed systems.

The main applications include:

- Medical industries: Packaging for medical equipment, injection components, electronic enclosures, and sterile disposable solutions.

- Electronics industry: Connectors, enclosures for printed circuit boards, and tiny mechanical components.

- Automotive industry: Interior parts, sensor frames, air ducts, and lightweight connection accessories that replace metal to reduce weight.

- Defense industries: Reinforced enclosures, lightweight structural components, and assemblies resistant to extreme environments.

- Agriculture industry: Connectors, irrigation systems, elements for agricultural machinery, and components exposed to sun and moisture over time.

Quality Control and International Standards

As parts become more complex and industrial requirements increase, the importance of strict quality control rises. Therefore, many tests are performed at every stage in plastic parts manufacturing.

It is important to comply with international standards, especially ISO standards for quality management. This is important not only from a legal perspective, but to build repeatable, documented, and controlled processes.

Advanced measurement systems collect data that allows analyzing trends and continuously improving the process.

About Admati Agencies

At Admati Agencies, we specialize in accompanying complex projects of components and parts for advanced industries, including high-precision plastic manufacturing solutions. Since 2007, we have been working with semiconductor, medical, and defense industries.

Thanks to an international partner network, an experienced technical team, and close familiarity with the needs of demanding industries, we are able to provide customized, precise, and reliable plastic solutions – and be for customers a single address for the entire design and manufacturing chain.

More News Articles