News

Introduction to Thermal Management: Keeping Devices Cool

What is Thermal Management?

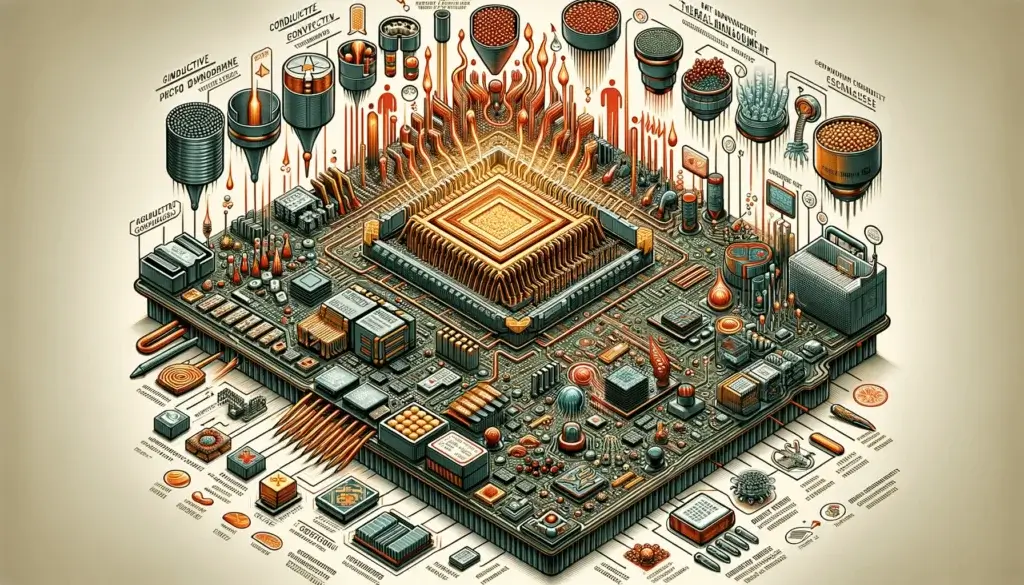

Thermal management is the process of managing heat within a system to ensure efficient and safe operation. By designing and implementing techniques that leverage conduction, convection, and radiation, thermal management helps regulate device or system temperature by removing or dissipating excess heat.

Thermal management is essential for many device and system types, including electronic devices, vehicles, power plants, imaging systems, and high-performance computing systems. Without proper thermal management these devices can overheat, leading to reduced performance, shortened lifespan, and potential damage to components.

Effective thermal management techniques, like heat sinks, fans, liquid cooling systems, and thermal interface materials, enable devices and systems to operate safely, perform at their best, and have a longer lifespan.

Thermal Management Techniques

Most systems use a combination of thermal management techniques, so these solutions are categorized based on the primary cooling method used in the system. Categorization is generally based on working fluid and the type of convection in the cooling system.

Air Cooling, Liquid Cooling, and Two-Phase Cooling

Thermal management solutions are classified into air cooling, liquid cooling, and two-phase cooling based on the working fluid used. While air cooling is often the simplest and most cost-effective solution, liquid cooling and two-phase cooling solutions provide more efficient heat transfer and are better suited for high-performance applications.

However, liquid cooling can have potential complications with compatibility and maintenance, and two-phase cooling solutions may require additional design considerations for managing the vapor-liquid interface. The best thermal management solution depends on specific application needs and the trade-offs between performance, cost, and complexity.

Why is Thermal Management Important?

Incorporating thermal management into the design process helps avoid costly redesigns or repairs. Industries such as medical, aerospace, defense, and eMobility have strict regulatory requirements for thermal management. Failure to comply with these requirements results in legal consequences, fines, or even loss of life.

Inefficient thermal management leads to increased energy consumption, which not only impacts the device’s performance and lifespan but also has a negative impact on the environment. This is a major design focus for industries like data centers and high power compute. By designing devices with thermal management in mind, energy consumption can be minimized, leading to a more sustainable product.

Touch temperature is an important factor in the user experience of a product. If a device or a component is too hot to touch, it poses risks of burns or other injuries to the end-user. This can also lead to negative media coverage, potential damage to brand value, and other legal liabilities.

Overall, thermal management should be an integral part of the design process to ensure reliable and safe operation, compliance with regulatory requirements, cost savings, environmental sustainability, and brand reputation.

Battery Thermal Management Systems

Thermal management is a crucial component for battery performance, especially in electric vehicles. The heat that is generated by the batteries during charging, discharging, and operation, can harm their capacity and shorten their lifespan. Excessive heat can lead to thermal runaway, a disastrous event that can result in fires or explosions. In order to maintain the optimal battery temperature and avoid safety hazards, effective thermal management systems is necessary. Lithium-ion batteries, due to their high energy density and sensitivity to temperature fluctuations, pose special difficulties. Traditional air or liquid cooling methods may not be sufficient to dissipate heat effectively, especially under high-load conditions. Common solutions include phase change materials, forced air cooling, and liquid immersion cooling. These systems help with battery temperature regulation, better performance, and longer battery life.

Advanced Thermal Management Solutions

In order to address the challenges of battery thermal management innovative solutions are constantly emerging. More effective heat dissipation is made possible by improved thermal conductivity provided by innovative materials like graphene and carbon nanotubes. New cooling technologies, like thermoelectric cooling and spray cooling, provide precise temperature control and can be integrated into compact battery packs. Compared to conventional techniques, these solutions provide a number of benefits, such as improved cooling efficiency, reduced weight and size, and enhanced reliability. They are used in various industries, including electronics, automotive, and energy storage. For instance, advanced thermal management systems are critical for guaranteeing the performance and safety of high capacity batteries in electric vehicles and energy storage systems.

Optimizing Thermal Management Systems

By optimizing thermal management systems you can substantially improve their efficiency, reduce costs, and enhance overall system performance. Computer simulations can be used to model battery behavior and predict thermal performance under different operating conditions. Machine learning algorithms are able to analyze large amounts of data to identify patterns and optimize cooling strategies. Smart control systems can dynamically adjust cooling parameters based on real time battery conditions, ensuring optimal temperature management. By optimizing thermal management, it is possible to save energy, reduce cooling costs, and improve battery lifespan. This is especially important for applications such as electric cars and renewable energy storage systems, where energy efficiency and cost effectiveness are critical.

More News Articles